SMTSurface mount technology (SMT) processing is one of the indispensable production and processing methods in today's rapidly developing electronics industry, and it is used for dense and miniaturized circuit boardsSMTIt is of great significance to carry out the mounting of components in the form of surface mount technology (SMT). However, some defects may occasionally occur during the production of SMT processing. Now, Shenzhen JJYSolder paste manufacturerHere's a brief introduction to the common reasons for component displacement:

SMTThe reasons for component displacement in surface mount technology (SMT) processing

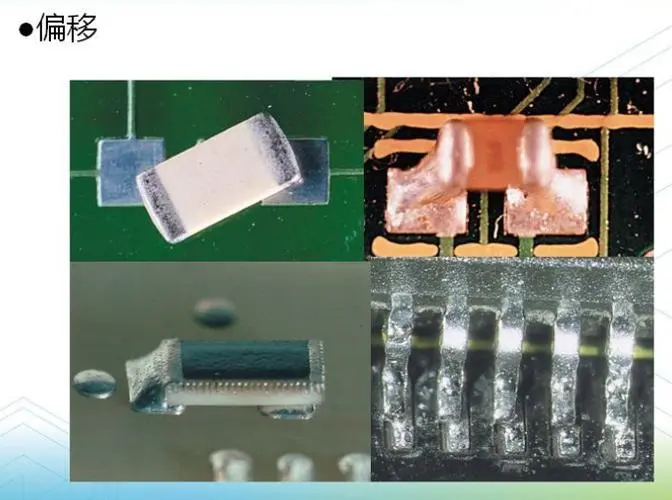

1There is a problem with the air pressure at the suction nozzle of the surface mount technology (SMT) machine, which does not meet the production standards. Insufficient air pressure can cause inaccurate placement of components, leading to displacement.

2The content of flux is too high, which leads to the displacement of components during the reflow soldering process.

3If the viscosity of the solder paste is insufficient, the components may experience a certain degree of vibration and shaking during transmission. At this time, the solder paste lacking viscosity may not be able to fix the components in their original positions, resulting in displacement.

4,SMTDuring the surface mount technology (SMT) process, the usage time of solder paste exceeded the standard requirements. Prolonged exposure caused changes in the flux, which led to poor SMT processing of the components.

5After the board is mounted, during the transmission process, due to oscillation or incorrect transportation methods, the components may shift.

6The problem with the surface mount machinery caused the incorrect placement of components.

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The solder paste we produce is of stable quality, without solder connection, false soldering or monument erection. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account