Solder joint quality is one of the important quality parameters in the production and processing of surface mount technology (SMT) processing plants. The quality of solder joints, whether good or bad, will directly affectPCBAThe circuit and working performance, service life, etc. Below is Shenzhen JJYSolder paste manufacturerLet me briefly introduce to you the common criteria for judging the quality of solder joints:

1Electrical performance

A good surface of the solder joint needs to form a stable alloy layer to ensure good electrical conductivity. False soldering and false soldering areSMTUndesirable phenomena that cannot be tolerated in surface mount technology (SMT) processing need to be avoided.

2Mechanical strength

The actual application environment of electronic products may be disturbed by factors such as vibration. The solder joints need to have sufficient mechanical strength to prevent components from loosening or falling off. The strength of the solder joints can be increased by means of increasing the soldering area and other methods.

3Solder quantity

The amount of solder also directly affects the quality of the solder joints. Insufficient solder may reduce the mechanical strength of the solder joints or shorten the service life of the product. Excessive solder may also cause short circuits and other issuesSMTThe poor processing phenomenon in surface mount technology (SMT) processing is usually appropriate when the solder covers the pad and spreads out in a skirt shape in actual processing and production.

4The surface of the weld points is bright and uniform

A good surface of the solder joint should be bright and have uniform color.

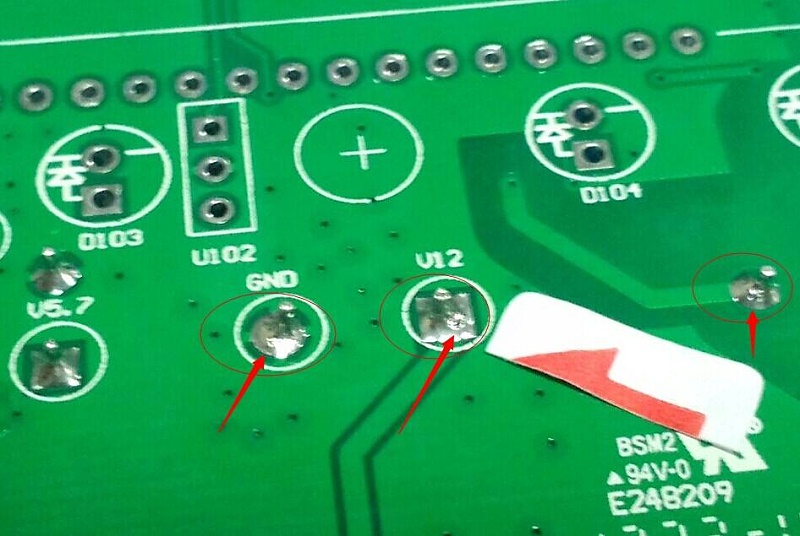

5The weld points are free of burrs and voids

The surface of the solder joints in general patch production and processing products should not have burrs, voids or other phenomena. Such phenomena not only affect the aesthetic appearance but also cause harm to people.

6The surface of the solder joint is clean

Residues on the surface of solder joints need to be removed in a timely manner to prevent them from corroding components, solder joints and circuit boards, etc.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account