inSMTThere are many factors in surface mount technology that can affect the final quality, such as the quality of surface mount components.pcbThe pad quality of the circuit boardSolder pasteSolder paste printing, placement accuracy of surface mount technology (SMT) machines, adjustment of reflow soldering furnace temperature curves, etc. Then among them, asSMTHow to choose the most commonly used auxiliary materials in surface mount technology (SMT), such as solder paste and flux? Below is Shenzhen JJYSolder paste manufacturerLet me explain:

First, distinguish product positioning and treat them differently

1The product has high added value and high stability requirements. Select high-quality solder paste.R(Grade)

2For those exposed to the air for a long time, anti-oxidation is required.RA(Grade)

3For low-end consumer goods with low quality requirements, choose solder paste of similar quality and lower price.RMA"

Ii. Device Material andPCBPad material

1,PCBIf the pad material is lead-tin plated, it should be selected63Sn/37PbThe solder paste.

2Components with poor solderability should be adopted62Sn/36Pb/2Ag.

Iii. Differential Selection of Different Processes

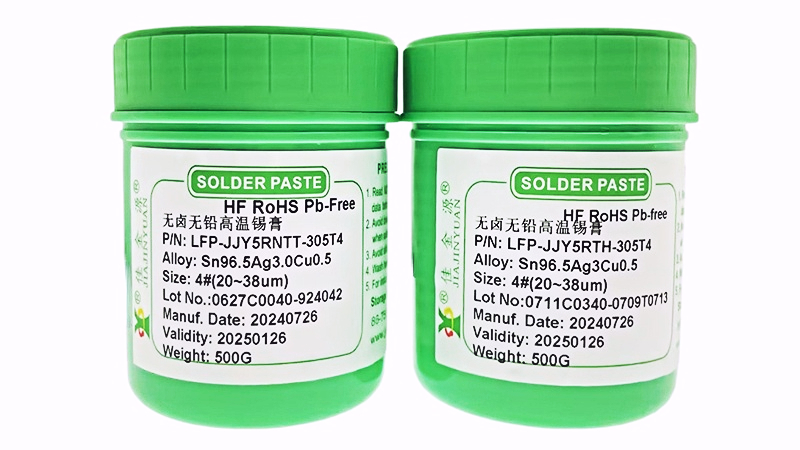

1Lead-free processes are generally chosenSn-Ag-CuAlloy solder.

2For no-cleaning products, choose weakly corrosive no-cleaning solder paste.

Iv. Welding Temperature

1For the welding of heat-sensitive devices with poor high-temperature resistance, those containing should be selectedBiLow-melting-point solder paste.

2High-melting-point solder paste must be selected for high-temperature devices.

With the increasingly higher requirements of the state for environmental protection standards,smtThe selection of auxiliary materials for solder paste surface mount processing also has corresponding environmental protection grade requirements. The application of more lead-free solder paste and no-clean solder paste is becoming increasingly popular and widely used. As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account