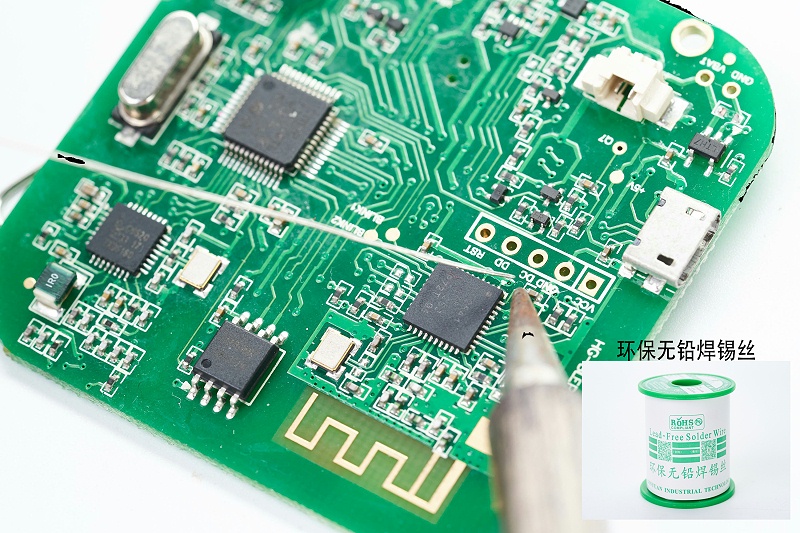

Everyone should have a question? This situation has been encountered: when the tin wire breaks during use due to the operation process, if the operator fails to pick out and cut off the joint in time. At this time, the joint remains in the tin wire. When the tin wire with a joint is used and soldered by a high-temperature soldering iron, the water vapor or air that may be contained inside the joint will rapidly expand. The gas will break through the liquid tin wrapped around it, causing "exploding tin". Why is that? Let's have the solder paste manufacturer explain it below:

What is "exploding tin"? During soldering operations, when the tip of a high-temperature soldering iron touches the solder wire, it suddenly makes a cracking sound and small tin beads pop out. This is the phenomenon of "exploding tin". The occurrence of solder wire explosion is very likely due to problems during the processing of the solder wire. During the production of solder wire, if there are cracks in the solder wire when passing through the wire drawing machine, the drawing oil will seep into the solder wire along with the cracks. When the oil comes into contact with fire, an explosion will naturally occur, which is known as solder wire explosion. It could also be that water has come into contact with fire. In places like Guangdong, where the rainy season is relatively humid and the air is filled with moisture, if the solder wire or the circuit board to be soldered is not properly stored and gets wet and damp, the solder wire may experience intermittent soldering.

This is to introduce the basics to everyoneSolder wireWhen there is a situation of tin explosion during the operation, everyone should pay more attention. If you want to know more details, generally, when processing solder wire, it is necessary to strengthen patrols to ensure strict operation of solder wire processing. If there are cracked areas, they need to be dealt with in time.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account