Everyone should knowSolder wireWhen doing manual soldering, a process is required to reflect the quality of the products produced by the manufacturer. This aspect is still quite important in the process production. Today, JJY solder Paste Manufacturer will explain the basic steps to you:

Basic steps:

(1Preparation before welding:

Before welding, confirm whether the iron in the circuit is at the allowable operating temperature. Only by choosing the appropriate contact position between the soldering iron tip and the solder joint can a good solder joint be obtained.

(2Correct welding operation5One step

1Prepare for soldering: Hold the welding wire in your left hand and the soldering iron in your right hand, and enter the ready soldering state. The soldering iron tip should be kept clean, free of slag and other oxides, and a layer of solder should be plated on its surface.

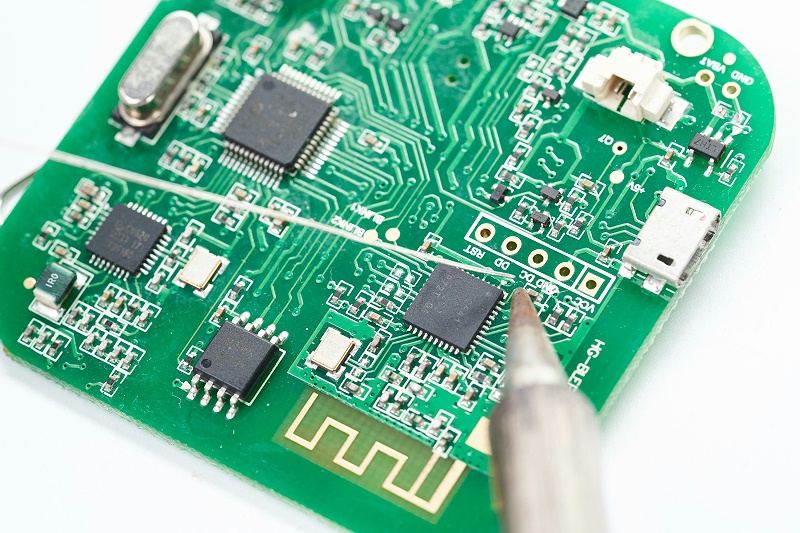

2Heat the soldered parts: Place the tip of the soldering iron against the connection of the two soldered parts and heat the entire soldered parts for approximately1-2Seconds. When soldering components on a printed circuit board, it is important to ensure that the tip of the soldering iron touches both the pad and the leads of the components simultaneously.

3When the soldering surface of the workpiece is heated to a certain temperature, the solder wire comes into contact with the workpiece from the opposite side of the soldering iron. Note: Do not send the solder wire to the soldering iron tip.

4Remove the welding wire: Once the welding wire has melted to a certain extent, immediately move it to the upper left45Remove the welding wire in the degree direction.

5Remove the soldering iron: After the solder has moistened the pad and the soldering area of the workpiece, move it to the upper right45Remove the soldering iron in the correct direction to complete the soldering.

The above is to tell you some basic knowledge, in this aspect the manufacturer can have a relative understanding, if there is anything you don 't understand, welcome to consult, so that for the future production can feel the quality guarantee problem, for your own brand also more popular !!!!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account