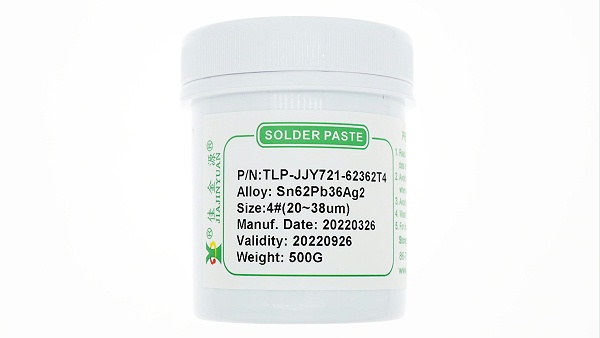

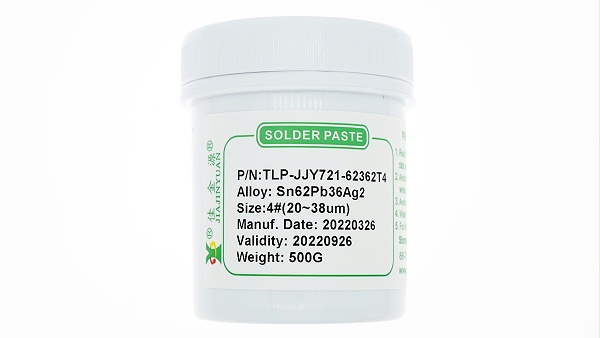

Brand:JIAJINYUAN/JJY

Model:TLP-JJY721-62362T4

Alloy composition:Sn62Pb36Ag2.0

Particle size:4#(20-38um)

Viscosity:60±10(Pa·S)

Activity: Weak activity

Melting point:179℃

Working temperature:210-225(℃)

Specification:500g/bottle

<="">

<="">

TLP-JJY721-62362T4Halogen-free leaded solder paste is made from a scientific formula and spherical solder powder with low oxidation degree. At the same time, it is refined with imported chemical materials to form a paste, which can achieve very high stability and effect. It has good demolding performance during printing, excellent dry resistance and good thixotropic performance, and can be applied to0.4mmThe printed solder paste for fine-pitch pads isRMAFlux and tin powder particles are uniformly mixed. Fewer solder beads are produced during welding, reducing the occurrence of short circuits. Applicable to0.4mmPrinting of fine-pitch pads and fine-pitchQFN,BGAThe mounting of devices. There is little residue after welding, with low corrosiveness. It has an extremely high surface insulation resistance value and can achieve excellent results without cleaningICTTest performance.

The on-time delivery rate is as high as99%

The on-time delivery rate is as high as99%

Suitable for high activityQFN/DFNDedicated scene for climbing Xigao;

Suitable for high activityQFN/DFNDedicated scene for climbing Xigao;| Project | gauge lattice | ginseng test mark quasi |

|

| stick Degree of | 160±10Pa.S | IPC-TM-650 |

|

| tin bead | PASS | IPC-TM-650 |

|

| Continuous printing capacity | 10More than one hour | IPC-TM-650 |

|

| Flux content | 10% | |

|

| Copper mirror corrosion test |

PASS |

|

|

| Surface insulation impedance value | Initial value |

1.0×1013Ω |

IPC-TM-650 |

| (SIR) | After the hot and humid weather |

1.0×1012Ω |

|

| Expansion rate | 90% | JIS-Z-3197(1999) |

|

| Viscosity retention | Qualified | IPC-TM-650 |

|

| Collapse test |

|

|

|

| Shelf life2~10℃) | 6One month | ||

| Printability | right0.4mmThe foot distance to the substrate is well printed |

|

|

<="">

<="">

<="">

<="">

in5-10℃The storage period under the environment is6Months, not less than0℃Store under such conditions and thaw before use2-4It should be left to room temperature for more than an hour before opening to prevent the formation of tin beads due to moisture. Then stir well before use.

in5-10℃The storage period under the environment is6Months, not less than0℃Store under such conditions and thaw before use2-4It should be left to room temperature for more than an hour before opening to prevent the formation of tin beads due to moisture. Then stir well before use.