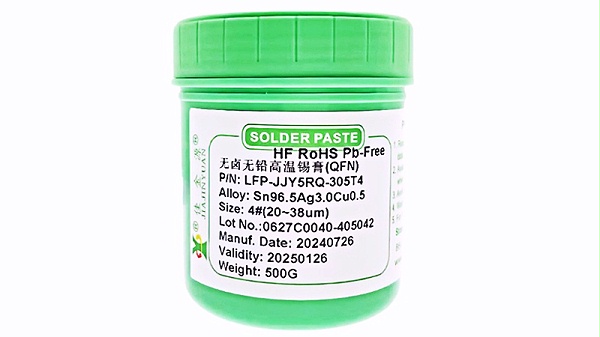

Brand:JIAJINYUAN/JJY

Model:LFP-JJY5RQ-305T4

Alloy composition:Sn96.5Ag3.0Cu0.5

Particle size:4#(20-38um)

Viscosity:190±20Pa.S

Activity: High activity

Melting point:217℃

Peak temperature:230-260(℃)

Specification:500g/bottle

<="">

<="">

Suitable for high activityQFN/DFNWaiting for scenes like climbing tin and so on; It has little residue and is transparent, and is well competent for the general spacing≧0.3mmThe printing of solder pads andQFN,BGAThe mounting of devices.

The on-time delivery rate is as high as99%

The on-time delivery rate is as high as99%

Suitable for high activityQFN/DFNWaiting for scenes like climbing tin and so on; Little residue and transparent;

Suitable for high activityQFN/DFNWaiting for scenes like climbing tin and so on; Little residue and transparent;

| Project | Parameters | |

| Appearance | The appearance is light gray, smooth and paste-like without layering | |

| Flux content(wt%) |

13%±0.5%

|

|

| Halogen content(wt%) |

<0.05%

|

|

| Viscosity(25℃whenpa.s) |

190±20Pa.S

|

|

| Particle volume(μm) | 25~45 | |

| The water jet takes impedance(Ω·cm) | >1×105 | |

| Silver tinate paper test | Qualified | |

|

Copper mirror corrosion test

|

PASS | |

| Surface insulation impedance test(Ω) | Initial value |

1.0×10

10Ω

|

| After the hot and humid weather |

1.0×108Ω

|

|

| Expansion rate(%) |

95%

|

|

| Tin bead test | PASS | |

| Note: The test method is applicableJIS.Z.3282andANSI/J-STD-006 |

||

<="">

<="">

in5-10℃The storage period under the environment is6Months, not less than0℃Store under such conditions and thaw before use2-4It should be left to room temperature for more than an hour before opening to prevent the formation of tin beads due to moisture. Then stir well before use.

in5-10℃The storage period under the environment is6Months, not less than0℃Store under such conditions and thaw before use2-4It should be left to room temperature for more than an hour before opening to prevent the formation of tin beads due to moisture. Then stir well before use.