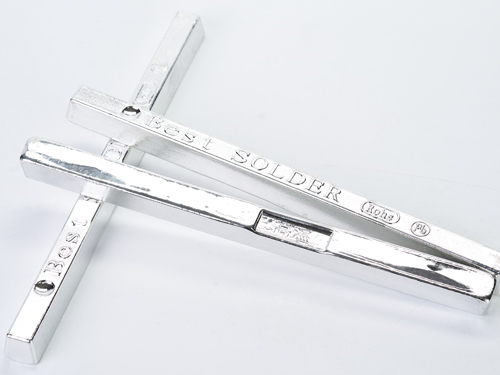

Product Name:Lead Free Solder Bar-Dip-Higher Temperature

Alloy:Sn95.5Ag3.8Cu0.7

Size(approx.):Trapezoidal Section(P18、Q25、H25)*L326 (MM)

Per Bar(approx.):1.105KG

Feature:Produced by pure tin and silver.Impurities are lowed to the minimum.

Application:For dip soldering process.

Packaging:Net weight 20KG/CTN

Shelf Life:2 Years

JJY Sn95.5Ag3.8Cu0.7 is designed as a lead-free alternative for Sn/Pb alloys for electronics assembly operations.

JJY Sn95.5Ag3.8Cu0.7 solder alloy was developed to have better fluidity and low drossing in dipping soldering process.

For stabilization of copper, Cu content in the soldering pot, JJY Sn96.5Ag3.5 alloy will be recommended as a top up solder.

JJY Sn95.5Ag3.8Cu0.7 is also developed to have better wetting and spread ability.

The on-time delivery rate is as high as99%

The on-time delivery rate is as high as99%

For dip soldering process with ROHS complianted.

For dip soldering process with ROHS complianted.

Specification

Specification

|

Item |

Specification |

|

Alloy Composition |

Sn95.5Ag3.8Cu0.7 |

|

Appearance |

Bright and shiny surface finishes |

|

Shape |

Bar |

|

Melting Point |

Approx. 217°C |

|

Density |

Approx. 7.5 g/cm³ |

|

Electrical Conductivity |

Approx. 13 %IACS |

|

Electrical Resistivity |

Approx. 13 μΩ.cm |

|

Soldering Temperature |

300-400°C |

|

Oxidation Resistance |

Good |

|

Amount of tin slag |

A small amount |