Product Description

product description

<="">

<="">

Lead solder wire for stainless steel welding is made by fusing high-purity tin raw materials from tin ore with electrolytic lead,It is refined through a special process; The rosin core of the product is made by boiling high-quality pure white transparent hydrogenated rosin in a vacuum sealed container with self-developed organic acid active agents. The process is special and reliable.

Scope of application

Scope of application

It is suitable for soldering on circuit boards, with fast tin application, bright and full solder joints, few tin explosions, good fluidity and high mechanical strength.

It is suitable for soldering on circuit boards, with fast tin application, bright and full solder joints, few tin explosions, good fluidity and high mechanical strength.

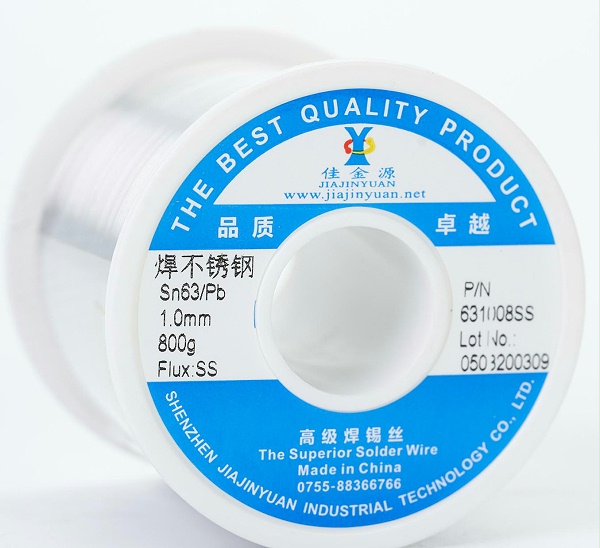

Product display

Product Show

<="">

<="">

<="">

<="">

Product Features

Product characteristic

- 1 Stable performance and safe to use Precise process control ensures that the rosin flux is evenly and continuously distributed, with no interruption of rosin. The soldering speed is fast, without sharpening or splashing. Customized tin wires with high compatibility can be made according to requirements.

- 2The weld points are bright and the workmanship is excellent Strictly adhering to national standards, it is made of high-purity virgin refined tin, electrolytic copper and pure silver materials, with few elemental impurities, sufficient degree, bright surface of the tin wire, uniform winding without tangling, little smoke and no unpleasant smell during welding, bright and firm weld points, and strong reliability.

- 3 It has good wettability and is easy to tin The self-developed flux can remove the oxide layer and surface oil stains of the soldered material, reduce the surface tension of the soldered material, increase the welding area, has good wettability, is easy to tin, and has no bridging.

- 4 Luoyang Iron has less scum and requires no cleaning Adopting a scientific rosin flux formula, it is strictly produced in accordance with national and EU standards, ensuring excellent solderability while guaranteeing low corrosiveness of the flux, fast welding speed and minimal residue after welding.

Product Description

product description

<="" iv="">

Lead solder wire for stainless steel welding is made by fusing high-purity tin raw materials from tin ore with electrolytic lead,It is refined through a special process; The rosin core of the product is made by boiling high-quality pure white transparent hydrogenated rosin in a vacuum sealed container with self-developed organic acid active agents. The process is special and reliable.

Scope of application

Scope of application

Used for compliance with all requirementsRoHSThe welding of environmentally friendly electronic components and other workpieces as instructed.

Used for compliance with all requirementsRoHSThe welding of environmentally friendly electronic components and other workpieces as instructed.

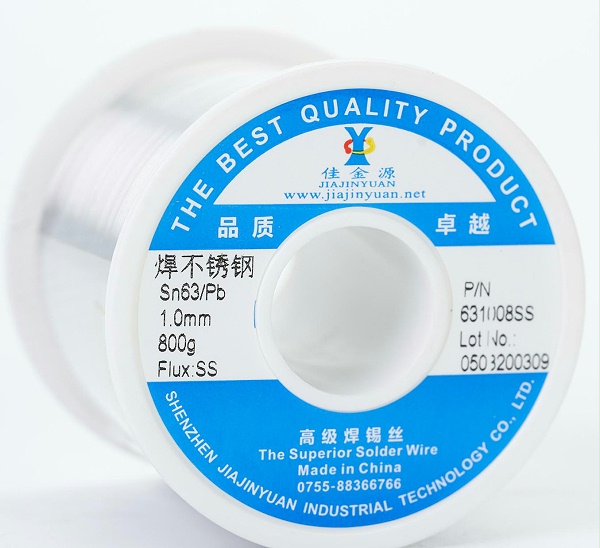

Product display

Product Show

<="">

<="">

<="">

<="">

Product Features

Product characteristic

- 1 Stable performance and safe to use Precise process control ensures that the rosin flux is evenly and continuously distributed, with no interruption of rosin. The soldering speed is fast, without sharpening or splashing. Customized tin wires with high compatibility can be made according to requirements.

- 2The weld points are bright and the workmanship is excellent Strictly adhering to national standards, it is made of high-purity virgin refined tin, electrolytic copper and pure silver materials, with few elemental impurities, sufficient degree, bright surface of the tin wire, uniform winding without tangling, little smoke and no unpleasant smell during welding, bright and firm weld points, and strong reliability.

- 3 It has good wettability and is easy to tin The self-developed flux can remove the oxide layer and surface oil stains of the soldered material, reduce the surface tension of the soldered material, increase the welding area, has good wettability, is easy to tin, and has no bridging.

- 4 Luoyang Iron has less scum and requires no cleaning Adopting a scientific rosin flux formula, it is strictly produced in accordance with national and EU standards, ensuring excellent solderability while guaranteeing low corrosiveness of the flux, fast welding speed and minimal residue after welding.

<="">

<="">

The on-time delivery rate is as high as99%

The on-time delivery rate is as high as99%

It is suitable for soldering on circuit boards, with fast tin application, bright and full solder joints, few tin explosions, good fluidity and high mechanical strength.

It is suitable for soldering on circuit boards, with fast tin application, bright and full solder joints, few tin explosions, good fluidity and high mechanical strength.

<="">

<="">

<="">

<="">

<="" iv="">

<="" iv="">

The on-time delivery rate is as high as99%

The on-time delivery rate is as high as99%

Used for compliance with all requirementsRoHSThe welding of environmentally friendly electronic components and other workpieces as instructed.

Used for compliance with all requirementsRoHSThe welding of environmentally friendly electronic components and other workpieces as instructed.

<="">

<="">

<="">

<="">