Everyone is quite clear that leaded solder paste is an indispensable auxiliary material for surface mount technology. Therefore, in this regard, everyone still needs to pay more attention to some situations of reflow. Below, the solder paste manufacturer will introduce some situations of soldering to everyone:

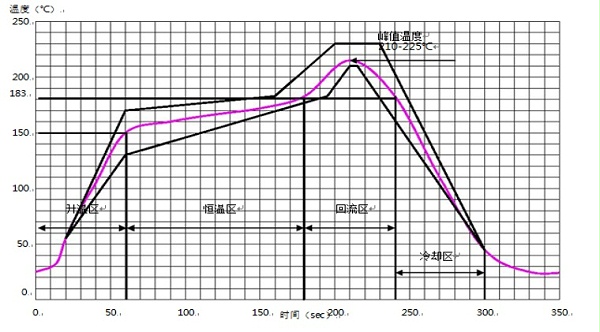

The reflow soldering temperature curve can be divided into three stages: preheating stage, heating zone, constant temperature zone, reflow zone and cooling zone.

Heating zone Heat and preheat the bottom of the substrate, and control the heating rate at2~3℃/During this period, the temperature rise in this area should be avoided from being too rapid to prevent the solder paste from having excessive fluidity, which could lead to the formation of solder balls.

Constant temperature zone Further heat the substrate to further activate the solder paste. This area is approximately90~120Seconds, reaching the preheating temperature170℃If the temperature is too low, it will affect the soldering condition.

Reference reflux temperature curve:

The above is what the editor has prepared for everyoneThere is lead solder pasteReflux temperature curve graph. I hope it can be helpful to everyone. However, the lead-containing solder paste from each manufacturer varies in terms of materials, applications, and other models. Of course, everyone should be quite clear about this. If you still have any questions, please feel free to consult us!