With the rapid development of the electronics industry and the continuous advancement of technology and manufacturing levels, electronic products are becoming increasingly sophisticated. The miniaturization and complexity of circuit boards, as well as the decreasing space between solder pads, have made traditional soldering processes unable to meet the requirements of some high-precision products. The main feature of laser soldering is to use the high energy of the laser to achieve rapid heating in a local or small area to complete the soldering process. In this aspect, it has a significant advantage. Now, Shenzhen JJY Solder Paste Manufacturer will explain it to you:

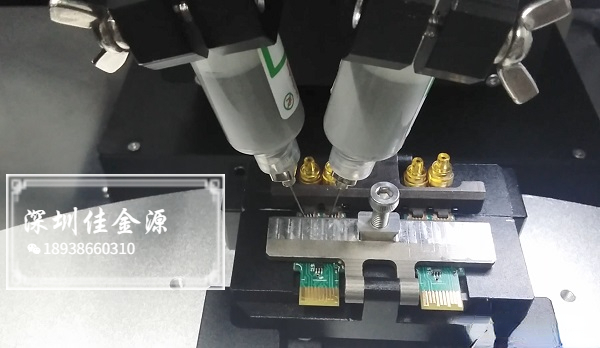

Laser solder pasteThe welding process is divided into two steps: Firstly, the laser solder paste needs to be heated, and the solder joint is also preheated. Afterwards, the laser solder paste used for welding is completely melted, and the solder paste fully wets the solder pad, eventually forming a weld. Due to the use of laser generators and optical focusing components for welding, the energy density is high, the heat transfer efficiency is high, and it is a non-contact welding method. If the solder is used, it is universalSMTSolder paste,This will result in problems such as tin explosion, splashing, tin beads, and poor wettability.

The advantages of laser solder paste soldering:

1Laser solder paste soldering only heats the local area of the solder joint and has almost no thermal effect on the solder pad and the component body.

2The weld points are rapidly heated to the set temperature and cooled quickly after local heating, quickly forming an alloy layer. The joint structure is fine and the reliability is high.

3Laser solder paste soldering is a non-contact processing. There is no stress generated when the soldering iron comes into contact with the solder, and no static electricity is produced.

4The temperature feedback speed is fast, and it can precisely control the temperature to meet the requirements of different welding.

5Laser processing has high precision, and the laser spot range can be controlled within0.2-5mmThe processing accuracy is much higher than that of traditional soldering iron soldering.

6Contactless welding, capable of meeting application requirements even for complex solder joints.

The above is an introduction to some of them for everyoneLaserSolder pasteWelding has some advantages. With the development of The Times, many products will become increasingly sophisticated. Therefore, it is inevitable that everyone needs to learn about it. If you want to know more about solder paste, lead-free solder paste, solder paste and other welding issues, welcome partners to consult Shenzhen JJY Industrial Technology Co., LTD.!