There are many manufacturers of leaded solder paste. It is believed that this product is quite common in soldering in some factories in daily lifeLEDIt can be seen in one of the automotive industry supplies and applications of secondary tube luminescence. Many customers don't know how to choose a manufacturer. Today, let the solder paste manufacturer's editor tell you how to choose a lead-containing solder paste manufacturer. Generally, the following aspects are considered.

The first thing to consider is the on-site usage environment, which is usually presentLEDThe automotive industry supplies, the application of secondary tube luminescence, and many other specific welding conditions related to this tea product have all been clarified first. Lead solder paste printing has good rolling and tin dropping properties, and is relatively low0.4mmThe pitch pads can also achieve exquisite printing. Leaded solder paste can meet the requirements of different grades of soldering equipment. It does not need to complete soldering in a nitrogen-filled environment and still shows good soldering performance within a wide reflow oven temperature range,Use heating up---Insulated type or Stepwise heating type Both types of furnace temperature setting methods can be used. Lead-containing solder paste leaves very little residue after soldering, has a very light color and a relatively large insulation resistance, and will not corrodePCBIt can meet the requirement of being washable .

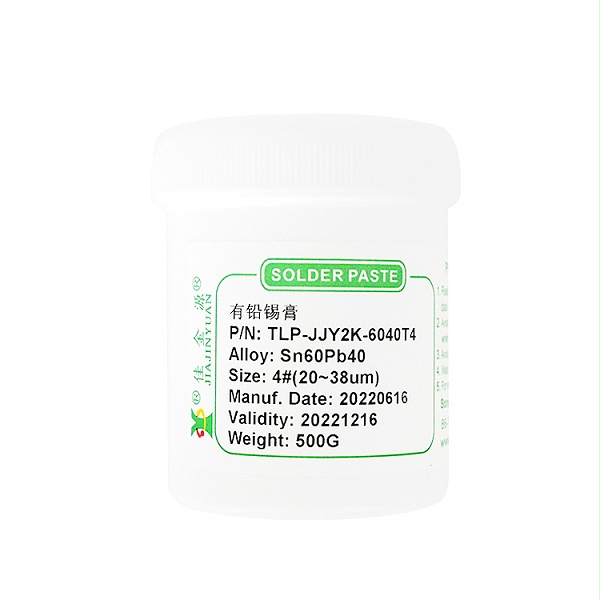

So when customers inquire about prices, they need to clearly state whether they want leaded solder paste or lead-free solder paste, as this will affect the price of the solder paste.

The above is all that the editor has explained to you aboutThere is lead solder pasteHere is a brief introduction. If you still don't know how to choose, you can directly call our sales team to learn more related knowledge!