Want to knowSMTSolder pasteWhy does surface mount technology (SMT) processing result in poor soldering due to insufficient solder? First of all, we need to understand what false soldering and false soldering are respectively. Then, let's have a brief introduction from the Shenzhen solder paste manufacturer:

False welding:It was welded but not completely, and it is prone to falling off.

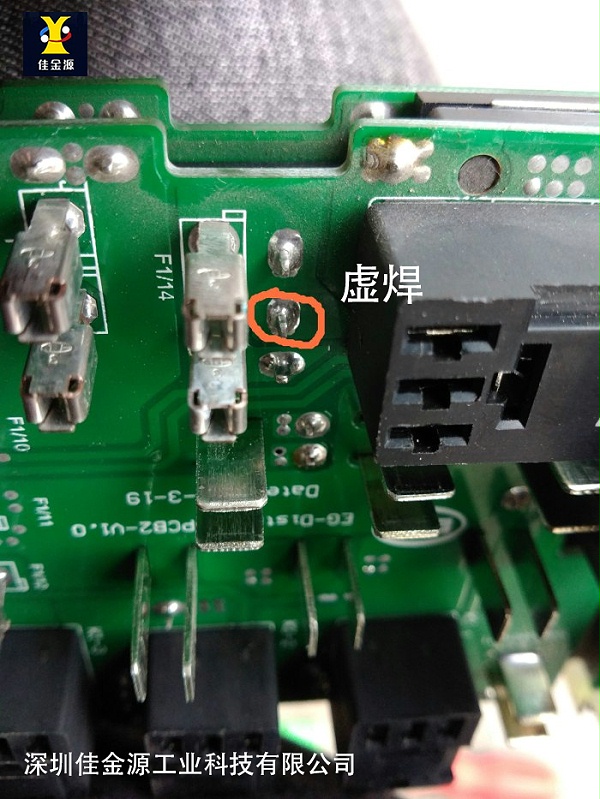

False welding:It seems to be welded on the surface, but in fact, it's not welded at all. It falls off at the slightest touch and is more likely to fall off than a false weld.

The reasons for false soldering :

1Poor solderability of solder pads and components:

2The printing parameters are incorrect;

3Improper reflow soldering temperature and heating rate;

Methods to solve the problem of false soldering:

1Strengthen the responsePCBAnd the screening of components;

2Reduce the viscosity of the solder paste and check the pressure and speed of the scraper;

3Adjust the reflow soldering temperature curve;

What is the essential difference between false soldering and false soldering? In fact, their essence is the same. There is a phenomenon of being neither welded nor welded in the welding process, such as gaps between the pins and the pads. In circuit representation, it is usually presented as time-off and time-on. False soldering only shows that the pins and pads do not come into contact with the naked eye from the outside. However, false soldering cannot be clearly detected from the outside, but there is a hidden danger of solder paste soldering. It is usually caused by reasons such as material oxidation and insufficient furnace temperature, resulting in poor soldering. However, false soldering and false soldering are often regarded as the same thing.

smtWhat causes false welding?

Component: Pin coplanarity, Pin solderability, Pin design, pin oxidation.

Solder paste: Lose activity, Insufficient tin content, Unreasonable openings in the mesh plate.

Furnace temperature: The temperature, reflow time and other factors do not meet the recommended standards. For instance, due to insufficient soldering temperature and time, the surface of the solder joint appears bright and everything seems fine, but in fact, the inside of the solder joint is a false solder, and the tin inside the solder feet turns grayish-white. This phenomenon indicates that the tin has not completely melted, and the solder pads, solder paste and pins cannot be fused together.

PCB: Unreasonable layout,inSMTIn reflow soldering, the higher components have a time effect on the lower components. This makesSMTThe components have uneven temperatures when passing through the furnace, resulting in false soldering.

You can appropriately use the soldering iron tip to solder the false soldering area. If it can be soldered again with the soldering iron tip, it might be caused by the solder paste and the furnace temperature.

Solution to false welding:

For general examinations, only a magnifying glass can be used,Some are really hard to tell and can only be known during the functional test.I think the preventive methods are:

1Before the surface mount,Be sure to keep it.PCBThe cleanliness of the welding surface,Appropriate cleaning or washing of the plates is provided.

2When scraping the paste, control the thickness and width of the solder paste reasonably.

3GuaranteeSMTThe surface mount technology (SMT) is in good condition,Try to put each component straight.

4Control the furnace temperature reasonably,Ensure the quality of tin dissolution,You can provide your solder paste supplier with a curve graph of reasonable furnace temperature.

5If there is any abnormality and the slurry has been scraped, it cannot be passed through the furnace immediatelyPCB,Deal with it promptly and properly(Such as refrigeration).The last point is to strengthen the skills training of personnel,Improve its recognition ability,In this way, most of the problems can be solved.

JJY, as a company that owns16A solder paste manufacturer with a long history, it has been committed to the research and development and production of solder paste for many years. The quality of the solder paste is stable, without solder connection and no monument erection. No residue, Wuxi beads, bright and full solder joints, firm solder joints, and good electrical conductivity. If you have any needs, please feel free to contact us.