With the rapid development of the electronics industry and the continuous advancement of technology and manufacturing levels, laser soldering processes and equipment have become increasingly mature. HoweverLaser solder pasteThere are also some differences from ordinary solder paste during the soldering process. These differences mainly lie in their application methods and performance characteristics. Next, let's have Shenzhen JJY Solder Paste Manufacturer explain some of their differences:

1Welding method: Laser solder paste achieves the welding process by heating and melting the welding material with a laser beam, while ordinary solder paste is usually melted and joined by traditional heating methods such as soldering irons or hot air guns.

2Welding speed: Laser solder paste usually has a faster welding speed because the laser can precisely control the heating area, achieving fast and accurate welding. In contrast, ordinary solder paste may require a longer heating time to complete the soldering.

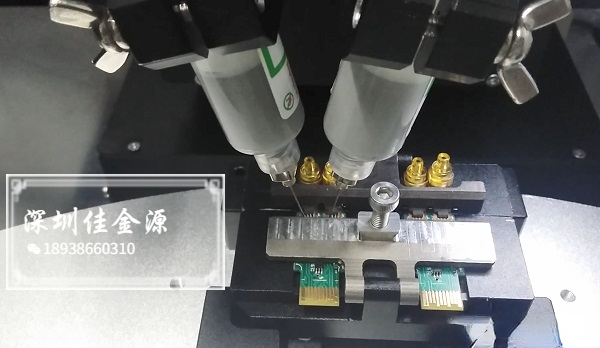

3Precision and control: Laser solder paste can achieve highly accurate soldering because the laser can precisely control the heating area and depth, thereby avoiding thermal damage to the surrounding area. Ordinary solder paste may have difficulty precisely controlling the heating area during the soldering process, which can easily lead to overheating or insufficiency.

4Scope of application: Laser solder paste is typically used in situations where high soldering accuracy is required and strict requirements are imposed on materials and the surrounding environment, such as the production of microelectronic devices. Ordinary solder paste, on the other hand, is more widely applied in manual soldering and mass production of electronic components.

Overall, laser solder paste has higher soldering accuracy, faster soldering speed and more precise heating control compared to ordinary solder paste, but its equipment and cost are also higher. Which solder paste to use depends on the specific soldering requirements and application scenarios.

Laser solder paste and ordinary solder paste do indeed have some differences in formula and composition, mainly to adapt to different soldering methods and requirements. The following are some of their differences:

1The composition of laser solder paste: Laser solder paste usually needs to have a higher light absorption rate in order to better absorb laser energy and heat up quickly. Therefore, the formula contains special additives or ingredients to make it more suitable for the laser welding process.

2The composition of common solder paste: Common solder paste is usually designed for soldering with traditional soldering irons or hot air guns, so its formula focuses more on having good fluidity and wettability under these traditional heating methods.

3Special requirements: Laser solder paste needs to have a higher thermal conductivity and thermal stability to adapt to laser welding. The high temperature and rapid heating requirements during the process. In contrast, ordinary solder paste pays more attention to ease of operation and stability during the general soldering process.

4Environmental factors: The formulation of laser solder paste also takes into account the impact on the environment, such as whether harmful gases or residues will be produced. Therefore, when designing laser solder paste, more environmentally friendly and low-emission components will be selected.

Overall, laser solder paste and ordinary solder paste differ in formula and composition according to their application methods and requirements to ensure their best performance in specific soldering processes. If there are specific soldering requirements, it is best to select the appropriate solder paste based on the actual situation.

16For many years, JJY has been dedicated to the research and development, production and sales of solder paste, providing customers with a complete set of electronic soldering solutions. If you want to learn more about solder paste, please keep following JJY Solder Paste Manufacturer and leave a message online to interact with us.