Solder pasteThe voids that occur during the printing and reflow processes are usually related to the undesirable phenomena in the soldering process. So, what are the differences between solder paste printing and the voids after reflow soldering? This article is briefly analyzed for everyone by Shenzhen JJY Solder Paste Manufacturer:

Solder paste printing stage:

1During the solder paste printing process, if the printing parameters are not set properly, such as the pressure of the squeegee, printing speed, and the number of squeegee applications, it may cause the solder paste to malfunctionPCBThe solder pads are unevenly distributed, resulting in cavities.

2The adhesion of solder paste is also an important factor. If the viscosity of the solder paste is inappropriate, or other characteristics andPCBSurface mismatch may also cause the solder paste to fail to adhere evenly, resulting in voids.

Reflux stage:

1During the reflow soldering stage, the volatile components in the solder paste (usually rheological agents) are heated and evaporated, forming bubbles. If the bubbles cannot escape effectively, it may also cause voids at the solder joints.

2Improper reflow soldering temperature may cause the residual gas on the pad to be unable to be completely discharged, thus forming voids.

Material quality:

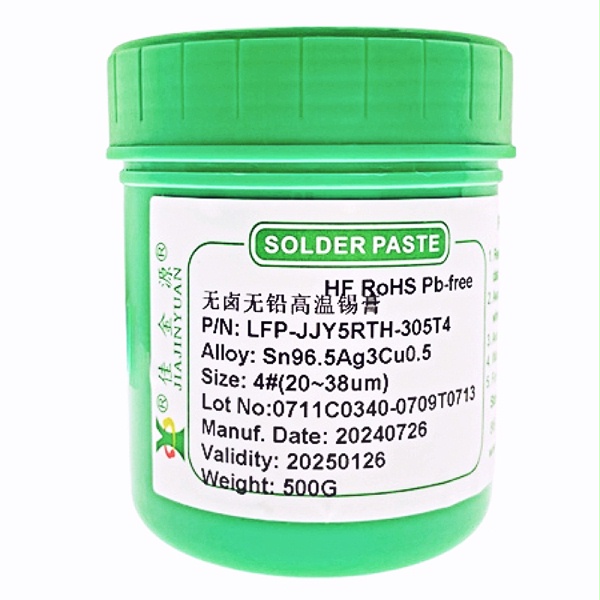

1Low-quality solder paste may contain defective components or have improper manufacturing processes, which may lead to the formation of voids during the reflow soldering process.

2,PCBThe surface coating and hygroscopicity of components and other properties may also affect the soldering quality, including the formation of voids.

The above is a brief introduction by JJY solder Paste Manufacturer to the differences between solder paste printing and reflow soldering voids. To solve these problems, it is usually necessary to comprehensively consider the factors of both the printing and reflow soldering stages. Appropriate printing parameters, high-quality solder paste, suitable soldering temperature and qualifiedPCBBoth components and components are key factors in ensuring welding quality and reducing voids.