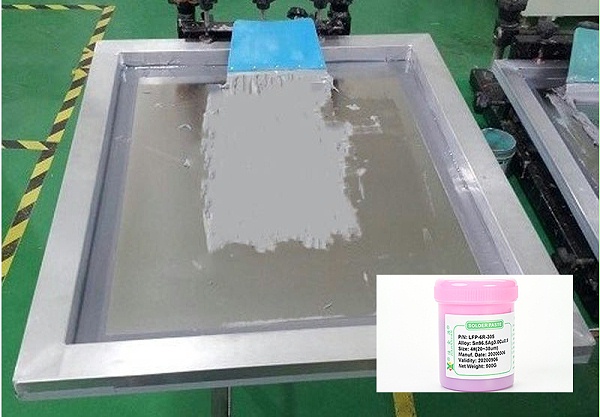

SMTSolder pasteThe main function of the steel mesh is to help the solder paste be accurately printedPCBOn the solder pads, it is inevitable that some solder paste will remain during this process. Generally, after use, it needs to be correctedSMTThe steel mesh should be cleaned to prevent solder paste from remaining on it and affecting its secondary use. To achieve a good cleaning effect and control costs, it is necessary to select the appropriate cleaning process and cleaning agent. Now, let's have JJY solder Paste Manufacturer explain itSMTWhat are the main cleaning processes for solder paste steel mesh?

1. Manual soaking and scrubbing method: Manual soaking and scrubbing refers toSMTThe steel mesh is immersed in the cleaning agent and cleaned by manual scrubbing. This cleaning method requires a small initial investment and does not need to purchase equipment. However, it is time-consuming and labor-intensive, fails to clean thoroughly, damages the steel mesh, and has a relatively high production cost.

Ii. Ultrasonic Cleaning Method: Ultrasonic cleaning utilizes the cavitation effect, acceleration effect, and direct flow effect of ultrasonic waves in liquids to directly and indirectly act on the liquid and contaminants, causing the contaminant layer to be dispersed, emulsified, and stripped, thereby achieving the cleaning purpose.

However, this type also has significant drawbacks. For instance, ultrasonic cleaning is not easy to thoroughly clean the mesh, especially for thick mesh plates, such as2.5mmFor the above-mentioned thick mesh plates, if the ultrasonic cleaner operates in this way over time, it will cause the adhesive of the stretched mesh to come off, which can easily lead to adhesive breakage and affect the tension of the steel mesh. It can also make the mesh surface prone to falling off, and it cannot compare with some steel mesh cleaning machine products under local ultrasonic technology.

Iii. Pneumatic Spray Cleaning Method: Spray cleaning is a type of chemical circulation cleaning. Its principle is to evenly spray the cleaning agent on the surface of the steel mesh, allowing the cleaning agent to fully contact the solder paste on the surface of the steel mesh, undergo a chemical reaction or dissolve and fall off, thereby thoroughly removing the solder paste and other contaminants on the surface. The advantages of spray cleaning are as follows: the surface is easy to rinse clean, there are no dead corners, the operation is simple, and pneumatic methods can be used.

As for the pneumatic spray technology, the main approach is to supply air through the air pump. Therefore, when the steel mesh cleaning machine is working, the air pump and other equipment must also be in operation. Additionally, if there is insufficient air supply or other situations during operation, uneven surface conditions may occur.

Four. Ultrasonic Spray Method: The ultrasonic combined with jet cleaning process is that the ultrasonic source is very close to the mesh plate, and an environmentally friendly water-based cleaning solution is sprayed in the middle. The cleaning solution will be shaken into the mesh holes by the ultrasonic force, and the residue in the cleaning holes will be cleaned. This cleaning process has a good cleaning effect, especially for the cleaning of red glue and thick mesh plates, but it requires a higher initial investment cost.

As a 16-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The solder paste quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.