SMTThe position of processing in electronic processing is becoming increasingly important with the development of miniaturization and precision of electronic products. There are also many points to pay attention to in the production process of surface mount technology (SMT) processing. If not careful, some processing defects that do not meet expectations may occur, and solder beads are one of them. The existence of tin beads is forSMTThe quality of surface mount technology (SMT) processing has a negative impact. At the very least, it affects the appearance; at worst, it may lead to poor bridging and other issues. Below is Shenzhen JJYSolder paste manufacturerLet me give you a brief introduction to tin beads.

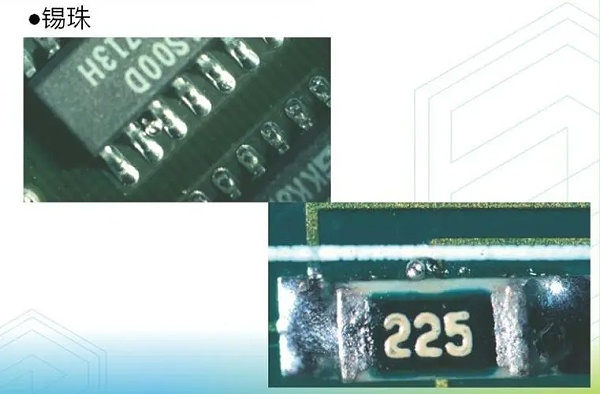

In realitySMTThere are mainly two types of tin beads that appear during processing. One type is an independent spherical shape on one side of the component, and the other type is some scattered small spherical shapesICAround the pins of the chip. Here, I'll briefly share with you some common causes of tin bead formation.

1. The temperature curve is incorrect

Reflow soldering isSMTThe general soldering process methods for surface mount technology (SMT) processing can generally be divided into preheating, holding, reflow, cooling, etc4In this area, the key role of preheating and heat preservation is to makePCBAThe surface temperature is60-90Rise within seconds150℃And do a good job of insulation, which is crucial for the subsequent welding and can be reducedPCBandSMTThe thermal shock suffered by the surface mount components can also ensure that a small portion of the solvent in the solder paste can evaporate, thereby preventing the solder paste from spilling out of the solder pad due to excessive solvent during the reflow soldering process and thus avoiding the occurrence of solder beads.

Solution:

Pay attention to adjusting the heating rate and do a reasonable preheating.

Ii. The quality of solder paste

1The composition of metals in solder paste is usually in(90±0.5)℅If the composition of the metal is too low, it will cause the composition of the flux to be too high. As a result, the excessive flux will cause flying beads due to its difficulty in volatilization during the preheating stage.

2,SMTThe increase in moisture and oxygen content in the solder paste during the surface mount technology (SMT) processing can also cause flying beads. Since solder paste is usually stored in the refrigerator, when it is taken out of the refrigerator, if it is not fully warmed up, thawed and stirred evenly, water will be added. In addition, the cap of the solder paste bottle should be tightly closed after each use. If it is not immediately closed tightly, it will also cause the addition of moisture.

3After the solder paste printed on the steel mesh is completed, the remaining part should be disposed of separately. If it is put back into the original bottle, it will cause the quality of the solder paste in the bottle to change and also form solder beads.

Solution:

It is required to use high-quality solder paste and strictly abide by the storage and usage requirements of the solder paste.

Iii. Other reasons

1The printing is too thick, and excessive solder paste overflows after the components are pressed down.

2The pressure of the surface mount is too high, and the downward pressure causes the solder paste to collapse onto the ink.

3The shape of the pad opening is not good and no anti-solder bead treatment has been carried out.

4The solder paste has poor activity, dries too quickly, or there are too many small tin powder particles.

The above content about the solder bead phenomenon was explained by Shenzhen JJY solder Paste Manufacturer. If you want to know more about solder paste products, please follow and interact with us.