What is leaded solder paste? Superficially, it is not difficult to understand.There is lead solder pasteAs the name suggests, it is a lead-containing solder paste and is also known in the industry as leaded solder paste. It isSMTIndispensable welding materials in the surface mount technology (SMT) industry. Leaded solder paste is composed of a mixture of soldering flux components and alloy components. Tin and lead are the main components of alloys, and thus are called leaded solder pastes. Now, the solder paste manufacturer will explain it to you:

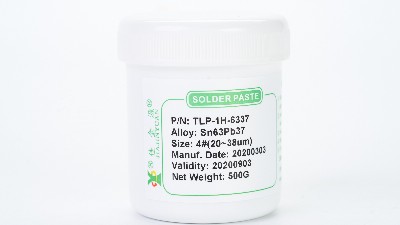

The composition of lead-containing solder paste depends on the type of solder paste. There are many alloy components in lead-containing solder paste, among which tin and lead are the main components. Besides these, the alloys of solder paste all contain trace amounts of impurity metal elements (such as iron, zinc, copper, aluminum, silver, mercury, arsenic, etc.). The most commonly used standard for leaded solder paste ingredients isSn63Pb37.

So, what exactly is the temperature curve setting for leaded solder paste reflow soldering? Let's take a look at leaded solder paste below63/37Here is a detailed introduction to the reflow soldering temperature zone Settings for you:

1The preheating zone, also known as the slope zone, is used forPCBThe temperature is raised from the ambient temperature to the required active temperature. In this zone, the temperature of the product should not exceed one second1~4°CThe speed keeps rising. If the temperature rises too fast, it will cause certain defects. If the temperature rises too slowly, the solder paste will be over-sensitive and will not have enough time to recoverPCBReach the active temperature. The preheating zone of the furnace generally occupies the entire length of the heating channel25%~33%. If the heating rate is too fast, it may cause the fluidity and deterioration of the composition of the solder paste, resulting in phenomena such as solder balls and bridging. At the same time, it will cause the components to be damaged due to excessive thermal stress.

2The active zone, sometimes called the dry or wet zone, usually occupies the heating channel33%~50%It has two functions. The first one is that it willPCBHolding at a relatively stable temperature allows components of different qualities to be homogeneous in temperature, reducing their considerable temperature differences. The second function is to allow the flux to be activated and volatile substances to evaporate from the solder paste. The general and common active temperature range is120~150°CIf the temperature of the active zone is set too high, the flux does not have enough time to be activated, and the slope of the temperature curve is an upward increasing slope. Although some solder paste manufacturers allow for a slight increase in temperature during activation, the ideal curve requires a relatively stable temperature, which makesPCBThe temperature is equal at the beginning and the end of the active zone.

3The reflux zone, sometimes called the peak zone or the final heating zone. The function of this area is toPCBThe assembly temperature is raised from the active temperature to the recommended peak temperature. The active temperature is always a little lower than the melting point of the alloy, while the peak temperature is always above the melting point. The typical peak temperature range is205~230°CIf the temperature in this area is set too high, the slope of the temperature rise will exceed one second1~4°COr reach a reflux peak temperature higher than the recommended one. This situation may causePCBExcessive curling, delamination or burning damage, and damage to the integrity of the component. The metal particles in the solder paste melt and form the surface of the solder joint under the action of the liquid surface tension.

4In the cooling zone, after leaving the reflow soldering area, the substrate enters the cooling zone. It is also very important to control the cooling rate of the solder joints. The strength of the solder joints will increase with the increase of the cooling rate. There is lead solder pasteSn63/Pb37Melting point183°C. The ideal cooling zone curve should be in a mirror image relationship with the reflux zone curve. The closer it is to this mirror image relationship, the tighter the solid-state structure of the solder joint becomes, the higher the quality of the obtained solder joint, and the better the integrity of the bond.

The above reflow soldering temperature curve is for reference only. The actual temperature setting needs to be comprehensively considered in combination with product properties, component distribution and characteristics, equipment process conditions and other factors. It is advisable to conduct more tests in advance to ensure the optimization of the curve. If you want to know more about solder paste products, please follow Shenzhen JJY Solder Paste Factory and interact with us.