insmtIn production, many customers have certain requirements for the glossiness of the solder joints. If the glossiness of the solder joints is found to be insufficient during the inspection process, the product can be defined as unqualified, thensmtWhat causes the insufficient gloss of the solder joints? The following is JJYSolder paste manufacturerjustLet me give you a brief introduction:

1The tin powder in the solder paste undergoes oxidation and thus decreasesPCBAThe glossiness of the solder joints.

2The solder paste itself contains additives that can cause a matting effect.

3,SMTIf the preheating temperature of reflow soldering in surface mount technology (SMT) processing is insufficient and does not reach the expected standard value, some non-evaporative substances will remain on the surface of the solder joint, thereby causingSMTThe glossiness of the solder joints is insufficient.

4InSMTAfter the soldering process, there are residues of rosin or resin on the solder joints. Generally, no-clean solder paste is selected. Although the flux of these solder pastes can make the solder joints brighter, in actual operation, their residues often have an impactPCBAThe glossiness of solder joints in surface mount technology (SMT) processing.

5,SMTThere is no clear standard for the gloss of solder joints in surface mount technology (SMT) processing. For instance, there will definitely be certain differences between products soldered with silver-free solder paste and those soldered with silver solder paste.

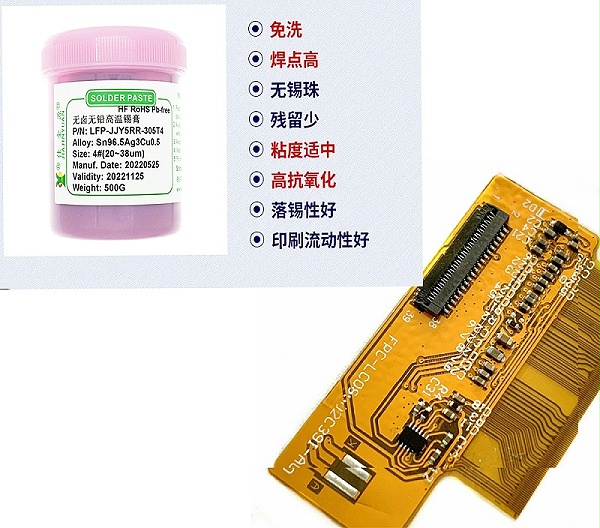

As a 15-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. The solder paste we produce is of stable quality, without solder connection, false soldering or monument erection. No residue, Wuxi beads, bright, full, firm solder joints with excellent electrical conductivity. If you have any needs, please feel free to contact us.