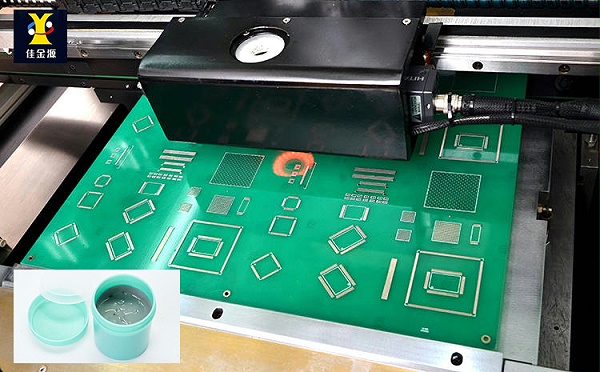

insmtIn the early stage of processing for surface mount technology (SMT) manufacturers, there is a very important step, and that isSolder pastePrinting. The quality of solder paste printing will directly affect our subsequent performanceSMTThe quality of processing and the wholePCBAThe quality of the board. Then what causes these production defects? What are the solutions? The following is a brief introduction from JJY solder Paste Manufacturer for you:

1. Tip the tip.

The cause of occurrence: It could be due to gaps in the scraper or excessive viscosity of the solder paste.

Solution: InSMTDuring surface mount technology (SMT) processing, appropriately reduce the gap of the squeegee or select solder paste with a suitable viscosity.

Second, the solder paste is too thin.

Cause of occurrence:1The template is too thin.2The pressure of the scraper is too high.3The solder paste has poor fluidity.

Solution:smtThe operators of the surface mount technology (SMT) manufacturers select templates of suitable thickness;Select solder paste with suitable particle size and viscosity;Reduce the pressure of the scraper.

Three, the thickness of the solder paste on the solder pads varies.

Cause of occurrence:1The solder paste is not mixed evenly, resulting in inconsistent particle sizes.2The template is not parallel to the printed circuit board.

Solution: InSMTBefore printing on behalf of others, thoroughly mix the solder paste;Adjust the absolute position of the template and the printed circuit board.

Fourth, the thickness is not the same, and there are burrs on the edges and surfaces.

The cause of occurrence: It could be that the viscosity of the solder paste is too low and the wall of the holes in the template is rough.

Solution: Select solder paste with slightly higher viscosity;Check the etching quality of the holes in the template before printing.

V. Fall. After printing, the solder paste sinks towards the middle of the solder pad.

Cause of occurrence:1The pressure of the scraper is too high.2The printed circuit board is not firmly positioned.3The viscosity of the solder paste or the metal content is too low.

Solution: Adjust the pressure;Fix the printed circuit board from the beginning;Select solder paste with suitable viscosity.

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow JJY Solder Paste Factory and leave a message online to interact with us.