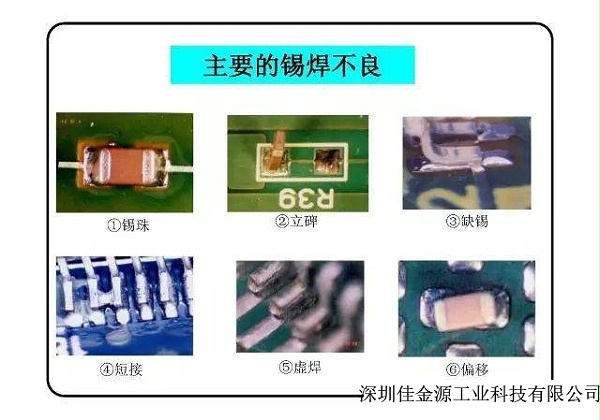

smtThe entire set of electronic processing procedures in it sounds simple, but in actual processing and production, it is still very complex and there are many details that are prone to problems, such as soldering defects.smtThe reasons for welding defects can be said to be numerous. But what are these reasons? The following is JJYSolder paste manufacturerLet me share with you the manifestations and causes of welding defects:

1. Poor wettability

Poor wettability is manifested in poor soldering of the solder pads or the pins of components.

Cause of occurrence:

1The pins or pads of the components have been oxidized/Pollution

2Too low reflow soldering temperature;

3The quality of the solder paste is poor

4Any of the above reasons can lead to poor wettability, and in severe cases, false soldering may occur.

2. Small amount of solder at the solder joints:

SMTThe amount of solder at the solder joints of the surface mount is relatively small, which is manifested as incomplete solder joints.ICThe crescent surface at the base of the pin is relatively small.

Cause of occurrence:

1The window (opening) of the printing template is small.

2Wick phenomenon (temperature curve difference mismatch);

3The solder paste has a low metal content.

4Any of the above reasons can lead to a small amount of solder and insufficient strength of the solder joint.

Iii. Damaged pins:

PCBAPin damage is manifested in poor coplanarity or bending of the device pins, which directly affects the soldering quality.

Cause of occurrence:

1Transportation/When taking or placing, if the components are damaged, they should be handled with care, especiallyFQFP.

Four. The solder pads are covered with contaminants:

Contamination of solder pads occurs frequently during production.

Cause of occurrence:

1Paper pieces from the scene; Foreign objects from the tape.

2Touch the solder pads or components by hand.

V. Insufficient solder paste:

Insufficient solder paste is also a surface mount technology (SMT) factorysmtA frequent phenomenon that occurs during processing.

Cause of occurrence:

1The first piecePCBAPrinting or restarting the printing after the machine has stopped;

2Changes in printing process parameters;

3The steel plate window (opening) is blocked.

4The quality of the solder paste has deteriorated.

Six. The solder paste is angular:

It often occurs in surface mount technology (SMT) processing production and is not easy to detect. In severe cases, it can lead to continuous soldering.

Cause of occurrence:

1The screen lifting speed of the solder paste printing machine is too fast;

2The walls of the template holes are not smooth, which can easily cause the solder paste to take on the shape of ingots.

As a 15-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development as well as production of solder paste for many years. Our solder paste is of stable quality, without solder disconnection, false soldering or monument erection. No residue, Wuxi beads, bright and full solder joints, firm solder joints, and excellent electrical conductivity. If you have any needs, please feel free to contact us.