inSMTDuring the manufacturing processSolder pasteThe printing result is correct.SMTManufacturing quality has a significant impact. Nowadays, it is also one of the solder materials that various electronic and electrical factories use surface mount technology (SMT) machines (reflow soldering machines) to mass-produce for surface mount electronic components, lamp beads, etc. Nowadays, forSMTFor manufacturers, ensuring product quality is the primary and fundamental issue. However, the soldering quality of solder paste is one of the key factors. Today, Shenzhen JJY Industrial Technology Co., Ltd. will tell you how to choose solder paste:

1.The alloy composition of the solder paste should be selected based on the assembly process of the product, the printed circuit board and the components, mainly according to the process conditions, usage requirements and the performance of the solder paste.

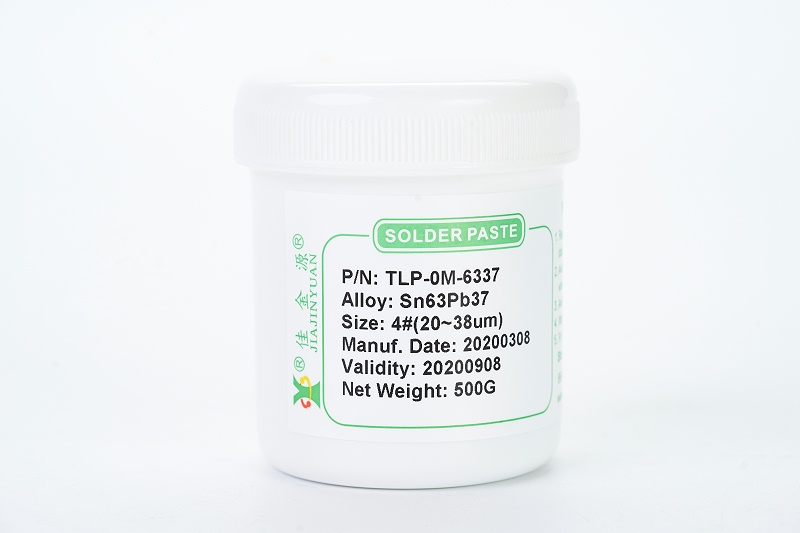

2.According toPCBThe particle size of the alloy powder is selected based on the assembly density (whether there is fine spacing or not). The particle size of the alloy powder commonly used for solder paste is divided into four particle size grades, and fine spacing is generally chosen20-45um.

3.According toPCBThe activity of solder paste should be selected based on the storage time of the components and the degree of surface oxidation. Generally adoptedKLRMAGrade. High-reliability products, aerospace and military products are available for selectionRGrade.PCBIt is adopted when it has been stored for a long time and the surface is severely oxidizedRAGrade. Post-weld cleaning.

4.Select solder paste based on the cleanliness requirements of the product (printed circuit board) and different cleaning processes after soldering.

When adopting the no-cleaning process, no-cleaning solder paste with low halogen content and no strong corrosive compounds should be selected. When using the solvent cleaning process, solvent-cleaning solder paste should be selected. When using the water cleaning process, water-soluble solder paste should be selected.BGA,CSPGenerally, high-quality no-clean silver-containing solder paste should be selected.

Solder paste is divided into two major categories: lead-free and environmentally friendly solder paste and ordinary lead-containing solder paste. Among them, lead-free and environmentally friendly solder paste is classified by melting point into high-temperature and medium-temperature types. Low-temperature solder paste The melting point of lead-containing solder paste is mostly183It's about a certain temperature, similar to that of environmentally friendly medium-temperature solder paste. If you need an environmentally friendly series for export, you should choose high, medium and low-temperature solder paste, or even environmentally friendly halogen-free solder paste. Otherwise, it is recommended to use leaded solder paste, which is cheap and easy to use. The brightness is relatively better than that of the environmentally friendly series.

In addition, pay attention to the selection of solder paste and solder powder:2-7#Tin powder is generally:3#powder25-45um,4#powder20-38umThe smaller the pitch of the component pins, in most cases, it is recommended to use finer tin powder, such as4#5#Tin powder, etc., to prevent the production of defective products.

Transportation and storage of solder paste: Solder paste needs to be refrigerated (not frozen), refrigeration temperature3-10During transportation, ice packs and insulated foam boxes are usually used for packaging. Additionally, there are also solder pastes that can be stored at room temperature.3-25The degree is the best.

Want to know aboutSolder pasteDear partners of solder paste, low-temperature solder paste, solder wire and solder bar, welcome to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account