With the development of China's industry, solder paste has evolved into a highly refined surface mount material, and it hasSMTIt has played an extremely important role in assembly technologies such as fine pin pitch device assembly and high-density assembly of surface mount devices. Nowadays, many users don't know how to chooseSolder pasteAnd each oneSTMWhen choosing solder paste, surface mount technology (SMT) manufacturers all hope to obtain solder paste with a lower price, thereby reducing production costs. However, solder paste with a low price does not necessarily meet one's own production needs. So, let's explain the selection criteria and requirements for solder paste below?

1The solder joints are fully tinned. This is90%For the requirements raised by the above-mentioned guests, to ensure that the solder joints are fully tinned, solder paste with appropriate activity and good wettability must be selected.

2There is no residue or whitening on the board surface. In the face of such requirements from customers, most manufacturers will choose no-cleaning solder paste. If the post-soldering whitening is indeed caused by the board issue, the post-soldering cleaning method can be adopted to solve the problem.

3Poor conditions such as Wuxi beads, continuous soldering or false soldering, and missed soldering. These conditions are relatively typical defects in electronic soldering, and generally, manufacturers will conduct relatively strict inspections and controls on them. To ensure good quality in production, the correct selection of solder paste is crucial. This is because choosing solder paste with appropriate activity and good wetting performance, combined with a good process, is the fundamental factor to avoid these defects.

4It has no leakage or other poor electrical performance. If the customer has such requirements, it is best not to choose solder paste with strong activity or high halogen content. If the condition of the board is poor and such flux must be used, we can solve the problem by cleaning.

In response to the requirements raised by these customers, as a solder paste manufacturer, only by truly meeting the customers' demands can it truly win their trust. The reasons for choosing solder paste:

Select the grade of solder paste based on the value of your own products and the application direction of the products. For some products with specified high requirements, high-quality solder paste is needed. Relatively speaking, the price of solder paste will be higher than that of ordinary ones.

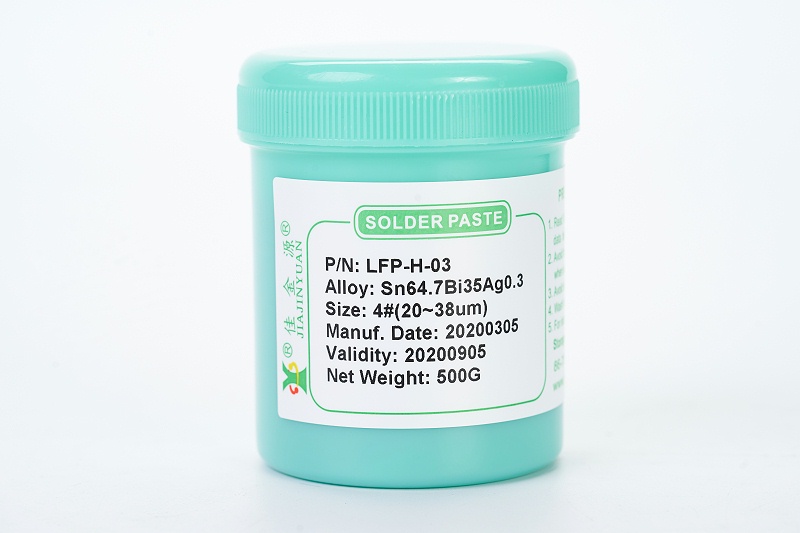

The application process and technology on different products are largely similar. The composition of solder paste should be selected based on individual circumstances. For instance, the amount of silver in lead-free solder paste varies in application.

Choose solder paste based on whether it can be cleaned. You can choose solvent-cleaning solder paste, water-soluble solder paste, or no-rinse solder paste (it is best to choose no-rinse halogen-free solder paste).

Different active solder pastes should be selected based on the storage time of the product and the degree of surface oxidation. Currently, they are widely usedSMTProduct, adoptedRMAGrade solder paste can meet the requirements. However, some products on aerospace and military equipment need to be adoptedRGrade active solder paste.

According toPCBThe particle size of the tin alloy in the solder paste is selected based on the structural composition of the plate.

Select solder paste of different viscosities based on the way of applying solder paste during production and the assembly density.

As mentioned above, leaded processing has better weldability than lead-free processing, but lead-free processing is more environmentally conscious. Want to know aboutSMTIn the patch Solder pasteFor other questions, partners are welcome to consult. Let's learn and grow together at Shenzhen JJY Industrial Technology Co., LTD.!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account