inSMTFriends who work in surface mount technology (SMT) factories all know thatSMTUsedSolder pasteIt is needed in2-8℃It is refrigerated and stored in the freezer. The purpose is to slow down the reaction speed of flux and tin powder to ensure that the components andPCBImprove the welding quality, thereby extending the quality of effective welding. Then inSMTWhy is solder paste stirred and warmed up before surface mount technology (SMT) processing? Perhaps many friends are not very clear about the real reason. Next, Shenzhen JJY Solder Paste Manufacturer will share it with you. We hope it can be of some help to you!

I. Why Stir

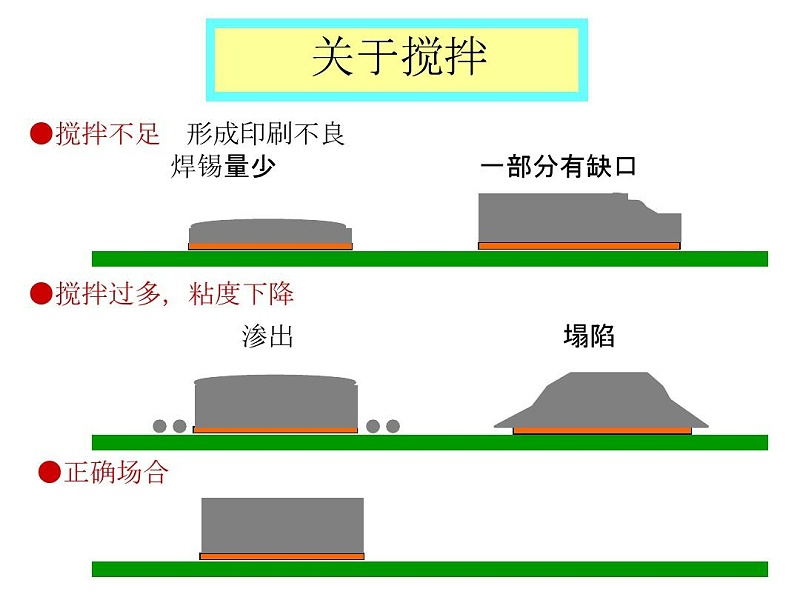

This brings us to the composition of solder paste. Solder paste is a paste-like mixture formed by mixing solder powder, flux, and other surfactants and thixotropic agents. It is accompanied bysmtThe new soldering materials produced by the surface mount technology (SMT) process are an important factor in ensuring the reliability of the reflow soldering process. Flux also contains different components, such as rosin, active agents, thickeners, etc. When these substances are left to stand for a long time, due to their own gravity, they will sink and precipitate and stratify, which will seriously affect the function of the solder paste. Therefore, before use, they should be stirred and remixed together for use. Since solder paste needs to be frozen during storage, its fluidity and uniformity will be affected. Therefore, before printing, solder paste should be thoroughly stirred to ensure that the flux and solder powder are evenly mixed, so as to achieve a good application effect. The general stirring time is1~4The minutes vary depending on the stirring method.

Ii. Why is it Necessary to warm up in Advance

This is because solder paste needs to be at a low temperature5-10Refrigerate at a certain temperature, then take it out of the refrigerator, keep the bottle cap sealed, and place it at room temperature2-4After a few hours, let its temperature balance with room temperature, and then open the bottle cap. And avoid arranging multiple bottles of solder paste closely during the warming process. If they are arranged too closely, the contact area with the environment will be reduced, affecting the warming effect.

The solder paste just taken out of the refrigerator will be at a lower temperature than the ambient temperature. If it is opened and used directly, the temperature difference can easily absorb moisture from the air and adhere to the surface of the solder paste. During the reflow soldering process, if the solder paste contains moisture, it will cause poor soldering, leading to cracked beads and the formation of solder beads. So before use, the solder paste needs to be opened and placed indoors2-4When the temperature is low, warm it up to make the temperature of the solder paste consistent with the ambient temperature.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account