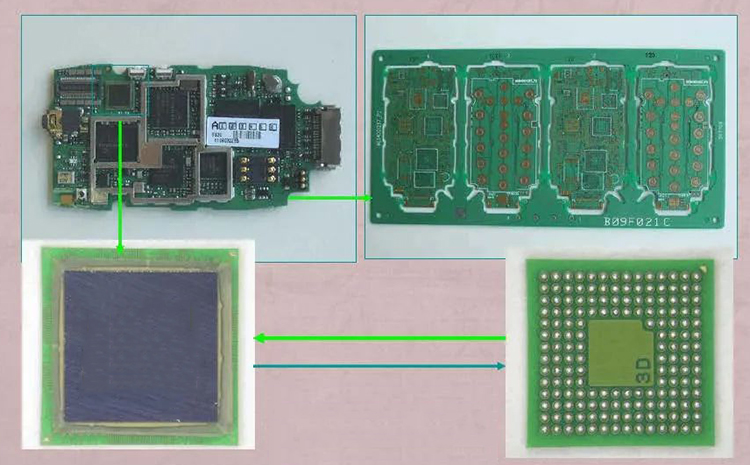

inSMTDuring the solder paste processing, the phenomenon of monument erection is a common issue, manifested as the lifting of the ends of components, which seriously affects the quality and performance of the products. At its core, the occurrence of the stele erection phenomenon stems from the imbalance of wetting forces at both ends of the component, which leads to an imbalance in torque and subsequently causes the component to tilt. Regarding this issue, Shenzhen JJYSolder paste manufacturerWe will conduct an in-depth analysis of the reasons for you and provide corresponding solutions:

I. Exploration of the Causes of the Monument Erection Phenomenon

1The force on both ends of the components is uneven, and the distribution of solder content is inconsistent, resulting in differences in wetting force.

2The preheating temperature setting is unreasonable and the heating rate is too fast, which affects the melting and wetting effect of the solder paste.

3Insufficient precision or improper operation of the surface mount technology (SMT) machine can lead to component placement deviation.

4The solder paste printing process is unstable, with poor thickness and position accuracy, resulting in uneven distribution of wetting force.

5Improper setting of the reflow soldering furnace temperature, either too high or too low, affects the melting and soldering effect of the solder paste.

6The nozzle is severely worn, resulting in inaccurate mounting position.

7Oxidation of the soldering coating at both ends of the component pins causes different wetting forces of the solder paste, resulting in wetting deviation or stele formation.

Ii. Solutions to the Phenomenon of Monument Erection

1Optimize the design of the steel mesh to ensure that the openings at both ends of the solder pads are consistent, so that the tin content is evenly distributed.

2Adjust the preheating and heating rate to ensurePCBThe board reaches the appropriate temperature in each temperature zone to facilitate the melting and wetting of the solder paste.

3Regularly inspect and adjust the precision of the surface mount machine to ensure the accurate placement of components.

4Adjust the parameters of the printing machine to improve the accuracy and stability of solder paste printing.

5According to the characteristics of the solder paste and the requirements of the components, set the reflow oven temperature reasonably to ensure the soldering quality.

6Regularly replace severely worn nozzles to ensure the accuracy of the mounting position.

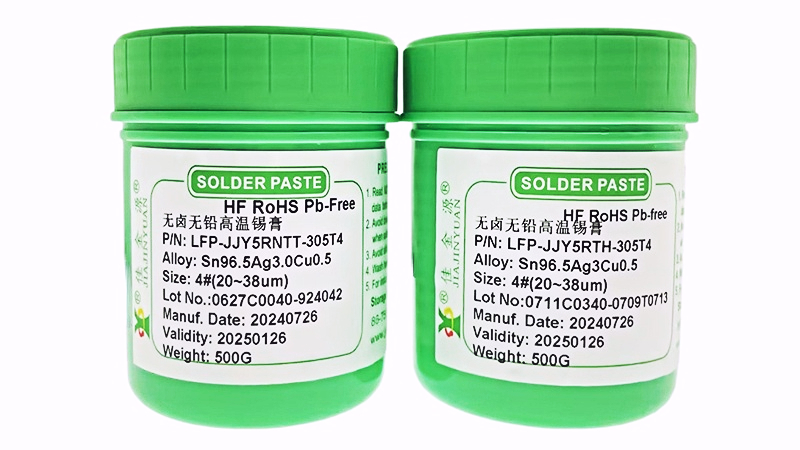

7Select components of stable quality to avoid causing oxidation problems of the coating. If the materials cannot be replaced, the occurrence of stele erection can be reduced by optimizing the furnace temperature curve or replacing the solder paste with better wetting performance.

JJY, with a history of sixteen yearsSolder pasteThe manufacturer has always been committed to the research and development, production and sales of solder paste. Our products are of stable quality and have the advantages of no solder connection, no false soldering, no monument erection, etc. The solder joints are bright and full, the soldering is firm, and the electrical conductivity is excellent. If you have any related needs, please feel free to contact us. We will serve you wholeheartedly.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account