insmtDuring the surface mount technology (SMT) processing, due to certain indispensable unstable factors, there are some problems with the quality of solder joints. rightsmtThe soldering situation in surface mount technology (SMT) processing usually has an acceptable range. If it exceeds a certain limit, it will affect the reliability of the product and it will be judged as a defective product. So next comes JJYSolder paste manufacturerLet's discuss it together with all friends:

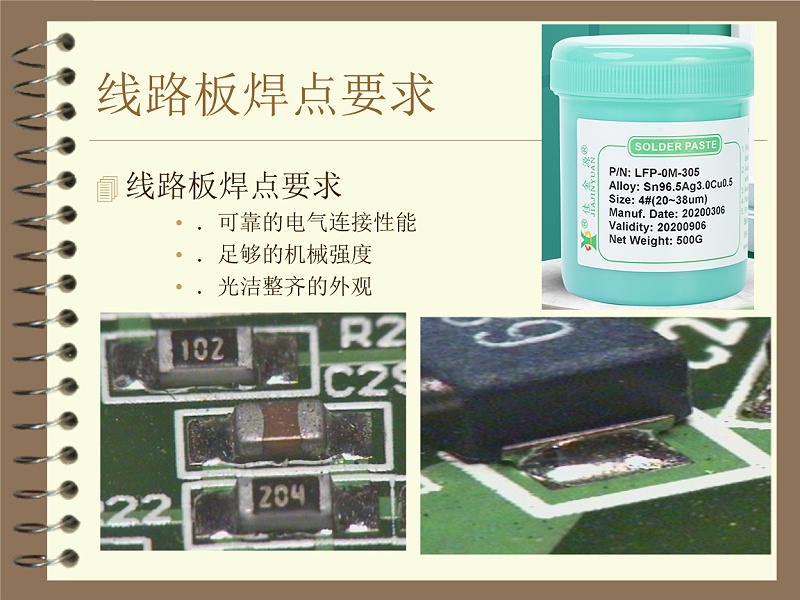

smtEvaluation criteria for solder joints in surface mount technology (SMT) processing

1The solder pads are not completely covered by solder. For non-circular solder pads with exposed corners and circular solder pads, it should be determined that the solder joint is poor.

2If the feet of the corroded parts or the green paint substance deteriorates and changes color, it indicates poor solder joints.

3The tin points of the tin tip component protrude beyond0.5mm. Fourth, solder that is cracked or has cracks

4The width of the solder joint is smaller than the width of the component soldering segment.W()75%Or less than the width of the padP()50%Then it is bad.

Failure analysis of surface mount technology (SMT) processing involves post-event inspection and analysis of failure phenomena related to the assembly process, such as solder joints, vias, and traces, which are determined to be failed based on performance failure criteria. The aim is to identify and determine the causes and mechanisms of failure related to the assembly process, and to feed back to the design, manufacturing, and user parties to prevent the recurrence of failure. To achieve the ultimate goal of improving the process reliability of electronic products.

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow the online message of JJY Solder Paste Factory to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account