The phenomenon of poor tin penetration isPCBAIt is worth our attention. Whether the tin penetration is good directly affects the reliability of the solder joint. If the tin penetration effect is poor after wave soldering, it is easy to cause problems such as false soldering. The following is JJYSolder paste manufacturerLet me give you a brief introductionPCBACountermeasures for poor penetration of solder in wave soldering during processing:

Requirements for wave soldering penetration rate:

The solder penetration rate of wave soldering points generally needs to be achieved75%The above means that the tin penetration rate of the panel appearance inspection should be higher than that of the board thickness75%The tin penetration rate is75%-100%All are fine. Wave soldering generates heat during the welding processPCBIf the oxygen outlet temperature is insufficient, poor tin penetration will occur during plate absorption. In order to makePCBThe plate can obtain more heat according to different typesPCBAdjust the corresponding tin-eating depth on the board.

Factors affecting the penetration rate of wave soldering:

Poor penetration of solder in wave soldering is mainly related to raw materialsPCBIt is related to factors such as the board, components, wave soldering process, the use of flux, and the level of manual soldering.

Raw material factors:

Under normal circumstances, melted tin has strong permeability, but not all metals can penetrate it. For instance, aluminum forms a dense protective layer on its surface, and its molecular structure makes it difficult for other molecules to penetrate. In addition, if there is oxidation on the metal surface, tin is also difficult to penetrate. It is necessary to treat it with flux or clean the oxide layer thoroughly.

Wave soldering process factors:

Poor tin penetration is closely related to the wave soldering process. It is necessary to reset and optimize the soldering parameters, such as wave peak height, temperature setting, soldering time and moving speed, etc. The track Angle can be appropriately reduced, the height of the wave peak can be increased, and the contact surface between the solder liquid and the pad can be raised;Then appropriately increase the temperature of the wave soldering. The higher the soldering temperature, the stronger the permeability of the tin. However, the soldering temperature should be within the temperature range that the component can withstand;Finally, the transportation speed can be reduced, the preheating and soldering time can be increased, so that the flux can fully remove the surface oxides, penetrate the solder joints and improve the tin penetration rate.

Flux factors:

To prevent re-oxidation during the soldering process, improper selection of flux, uneven spraying, and excessive or insufficient usage can all lead to poor tin penetration. First of all, it is necessary to choose a regular brand of flux, which will have a better effect. In addition, the flux nozzle should be inspected regularly to prevent it from being clogged or damaged.

Artificial welding factors:

In the quality inspection of wave soldering, for some components, only the surface solder joints form a conical shape, while there is no solder penetration in the through holes, resulting in false soldering. Similar problems usually occur in manual welding, mainly due to insufficient welding temperature or too short welding time. Poor penetration of solder in wave soldering can easily lead to false soldering, thereby increasing the cost of manual rework. The tin penetration rate of selective wave soldering is much better than that of wave soldering. If the product has high requirements for soldering quality and tin penetration rate, selective soldering can be used, which can reduce the problem of poor tin penetration to a certain extent.

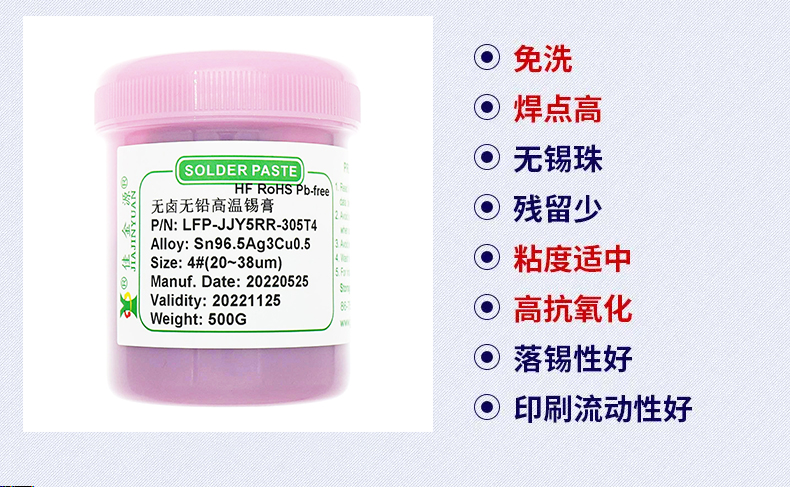

Shenzhen JJY Factory offers halogen-free lead-free solder paste, lead-free solder wire and other soldering products, and provides knowledge and question analysis on soldering for everyone. If you have any needs or more technical questions about soldering, you can follow JJY Solder Paste Factory's online message to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account