inSMTThe quality of solder joints is one of the key factors in the production, processing and inspection of surface mount technology (SMT) processing plants, as it directly affects the quality of solder jointsSMTThe overall quality of surface mount technology (SMT) processing and the reliability of solder joints also directly affect the reliability of electronic products. Below is Shenzhen JJYSolder paste manufacturerLet me briefly introduce to you the common quality inspection standards for solder jointsSMTThe contents of the appearance inspection for processing.

SMTQuality inspection of solder joints in the surface mount technology (SMT) processing factory

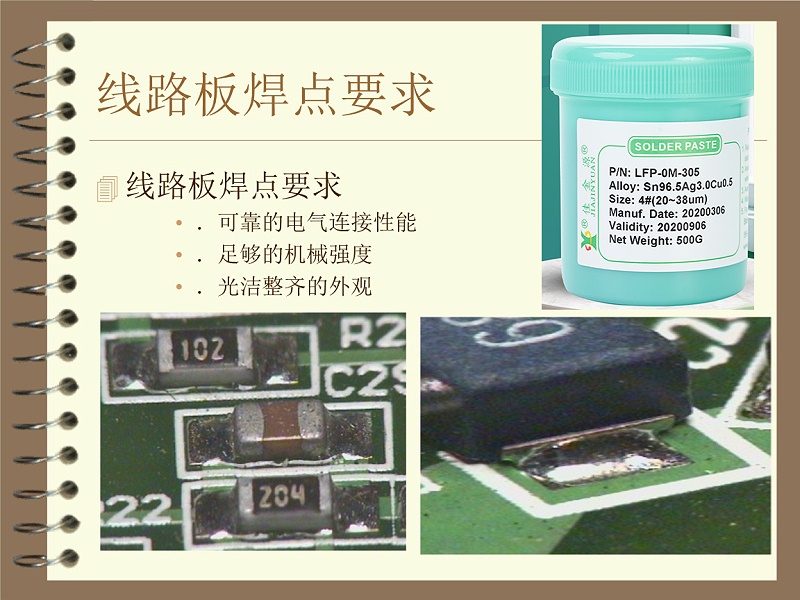

I. Solder Joint Inspection:

1The surface of the solder joints should be complete, smooth and bright, and there should be no defective solder joints.

2The height of the components should comply with the requirements of the process documents, the amount of solder should be appropriate, and it needs to fully cover the soldering areas of the pads and pins.

3The solder joint is required to have good wettability, and the edge of the solder joint should be relatively thin. The wetting Angle between the solder and the surface of the solder pad should be less than300The following is good. The maximum shall not exceed600;

Ii. Visual Inspection:

1No components were omitted.

2The components are not pasted incorrectly.

3There must be no short circuit phenomenon.

4There must be no false welding or cold welding phenomena.

JJY Solder Paste Manufacturer mainly engages in lead-free solder paste.SMTSurface mount solder pasteLEDWe are engaged in the research and development, production and supply of solder pastes, lead-free solder wires, wave soldering rods and other solder solders. For more knowledge about electronic soldering, you can follow and contact us. Welcome to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account