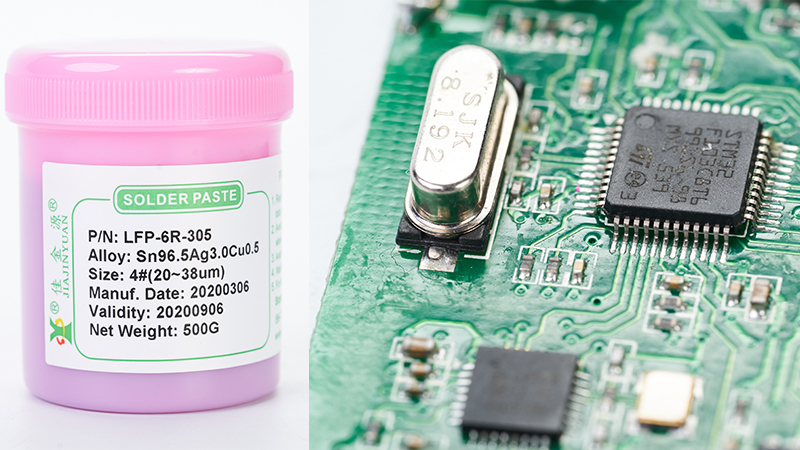

inSMTDuring the surface mount technology (SMT) production process, soldering defects occur from time to time. The common defects mainly include solder beads (solder balls), short circuits, misalignment, stele standing, and empty soldering, etc. The causes of these adverse phenomena are due to multiple factors. To avoid the occurrence of these adverse phenomena, it is necessary to have a clear idea and analyze the adverse problems step by step in order to solve the fundamental problems. Next up is Jia JinyuanSolder paste manufacturerAnalyze for everyoneSMTAnalysis and Summary of Common Defects in Surface Mount Technology (SMT), hoping to be of some help to you!

1. Solder beads are produced during welding/The main reason for the tin ball

1The reflow soldering heats up too quickly;

2The solder paste was refrigerated and not fully thawed before printing.

3The solder paste was not laminated and soldered in time after printing, resulting in solvent evaporation.

4Excessive pressure during the surface mount process caused the solder paste to overflow.

5,pcbImproper storage of the board and excessive humidity;

6The solder paste particles are not suitable.

7The opening design of the steel mesh is unreasonable.

Ii. Main Causes of short circuits in welding

1The peak temperature of reflux is too high or the reflux time is too long;

2The steel mesh design is unreasonable, resulting in poor demolding effect after solder paste printing.

3The solder paste is too thin and the metal content within it is low, which makes the solder paste prone to collapse and cause a short circuit.

4The printing pressure was unreasonable, resulting in the collapse of the solder paste shape.

5The solder paste particles are too large and the surface tension of the flux is too small.

Iii. Main Causes of Welding Deviation

1,pcbaThe pad design does not match the pins of the components.

2The solder paste is not active enough.

3Insufficient surface mount accuracy;

Iv. Main Reasons for the Erection of Monuments Caused by Welding

1The patch is offset, resulting in uneven force distribution on both sides.

2The solder pads are partially oxidized, resulting in poor tinning effect and uneven force distribution at both ends.

3If the solder paste is left for a long time after printing, the volatile activity of the flux will decline.

4,PcbThe local temperature of the surface components is uneven, and the force is uneven after melting.

V. Main Causes of Empty Welding in Welding

1,pcbThere are wires passing through the holes around the solder pads, and liquid tin flows into the holes during reflow.

2Uneven heating causes the component pins to overheat, preventing the solder paste from being introduced into the pads.

3Deformation or oxidation of component pins leads to poor soldering during reflow soldering.

4The commonality of the components is not good, resulting in incomplete contact with the solder pads.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account