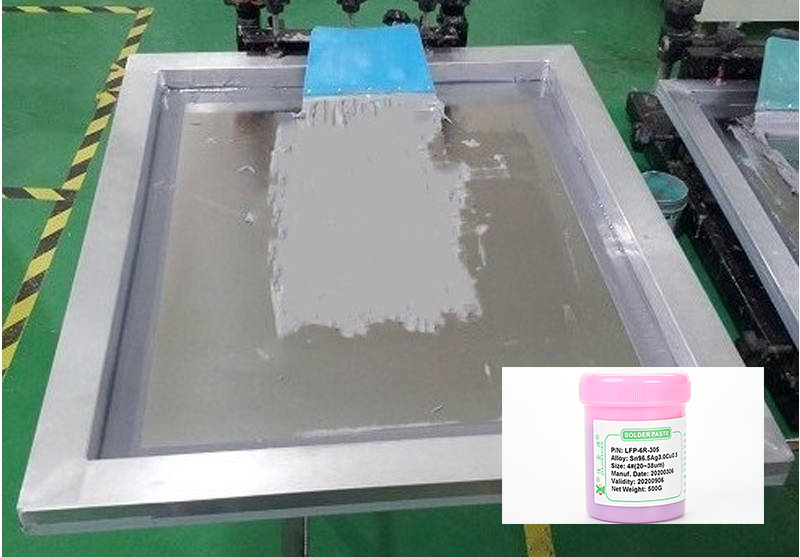

With the increase and complication of the functions of electronic products,Solder pastePrinting is becoming more and more refined. With othersSMTCompared with other technologies, solder paste printing technology still has many variables, and some of them are even difficult to control. The solder paste printing process has numerous potential instabilities. According to the latest research results, the printing process has60%The above-mentioned variability. The reason for such great variability is that the printing process involves a large number of uncertain process parameters, including the type and formula of solder paste, environmental conditions, the type and thickness of steel mesh, the width-to-thickness ratio and area ratio of openings, printing machines, scrapers, printing head technology, printing speed, and so on. Now, JJY solder Paste Manufacturer will explain it to you:

When it comes to the thickness of the printed steel mesh,smtThe thickness standard of solder paste is most closely related to this factor. We often use it in examples0.12mmThe thickness of the solder paste on the steel mesh, usually we open the thickness of the steel mesh0.12mmWhen we go to print, we think that the thickness of our solder paste printing is0.12mmBut in fact, it is wrong, because according to the printing process, in ourPCBThere is a certain gap between the plate and the steel mesh. During the solder paste printing process, the solder paste will fill this gap, and then the mesh will come off. When we test this thickness, it can be imagined whether the solder paste is thicker than the steel mesh. How much is that?smtWhat about the standard for solder paste thickness? This requires us to constantly define it in our learning, becausesmtThere is no international standard definition for solder paste thickness yet. There are only various different judgment criteria. However, one thing remains unchanged: the best amount of solder paste for printing is the good effect of soldering.

AboutSMTThere is no standard definition for the thickness of solder paste. Usually, it is determined based on the process of the screen printing machine.PCBIt is determined by the components on the circuit board. The thickness specifications of steel mesh are as follows0.1mm,0.12mm,0.13mm,0.15mm,0.18mm,0.2mmWait, usually0.12mmThick steel mesh, the thickness of the solder paste is usually0.1mm-0.16mmAt present, it is quite suitable between them0.12mmThe proportion of steel mesh thickness is the largest. Beyond this range, there will be more or less some defects in the solder paste soldering.

SMTReference calculation formula for solder paste thickness:

Center value of solder paste thickness=Steel mesh thickness+0.025mm

Solder paste thickness=Central value±0.035

Minimum thickness of solder paste=Steel mesh thickness-0.01mm

Maximum thickness of solder paste=Steel mesh thickness+0.06mm

As a 15-year-old veteran solder paste manufacturer, JJY has been committed to the research and development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account