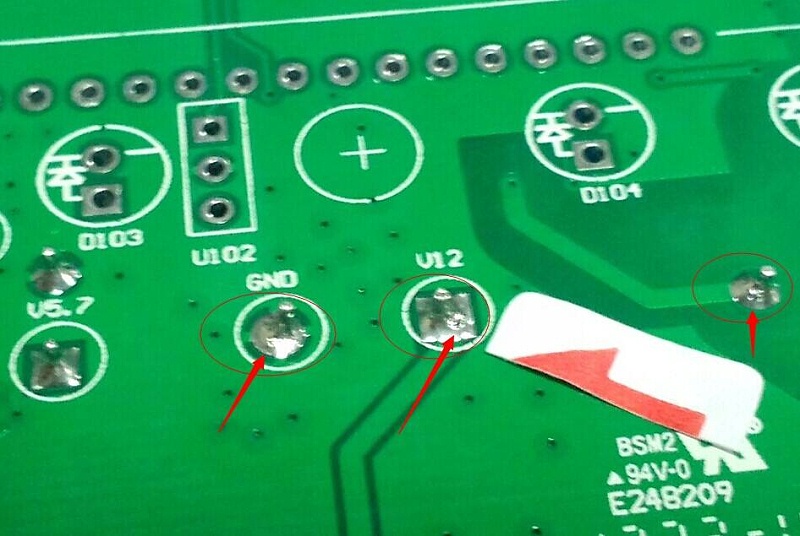

Recently, quite a few customers have been asking why they are using itLead-free solder pasteWhen welding, some bubbles may appear at the weld points from time to time. Does it have any impact on the product? Now let me tell you all that the appearance of bubbles in the solder joints is quite serious. If bubbles appear inside the solder joints, it not only poses a significant threat to the stability of the solder joints but also increases the probability of component failure. Today, JJY solder Paste Manufacturer will share with you how to solve the problem of bubbles produced by lead-free solder paste during soldering:

Why do bubbles occur during welding?

The formation of bubbles in solder joints is usually due to the flux in lead-free solder paste. Compared with ordinary solder paste, the alloy used in lead-free solder paste is also larger than the tin-lead alloy in ordinary solder paste, and the melting point of lead-free solder paste is higher. The flux also needs to function at a higher temperature, which greatly increases the possibility of volatile substances getting trapped in the molten solder before evaporation.

Another reason is that ordinary air reflow soldering equipment cannot create a vacuum environment inside, and thus cannot effectively remove the oxygen inside the furnace and the bubbles inside the solder joints. To prevent the oxidation of the solder joints, the reflow soldering furnace is filled with nitrogen. When the pressure of the nitrogen is higher than the atmospheric pressure, it will instead cause more bubbles to be produced inside the solder joints.

How to solve the problem of bubbles produced by lead-free solder paste during soldering?

Due to the characteristics of the constituent metals and fluxes of lead-free solder, it is difficult for us to directly avoid the formation of bubbles. So, how should we solve this problem? Although it is difficult to avoid the formation of bubbles, we can remove the bubbles inside the solder joints through some methods.

Firstly, we can perform gradient vacuuming right after the welding is completed and before it cools down. That is, the vacuum degree gradually increases. Since the solder has not yet solidified after welding, at this time, bubbles are scattered at various positions of the weld point. Gradient vacuuming can first remove the bubbles from the surface, while the bubbles at the bottom will gradually move upward. As the pressure decreases, the bubbles will evenly float out. If we instantly evacuate the air, the internal bubbles will quickly overflow, leaving explosive openings on the solder joints and also affecting the stability of the solder joints. In addition, pre-vacuuming should be carried out. Before heating lead-free solder paste, the oxygen in the working area should be evacuated to prevent the formation of an oxide film on the solder during the heating process. The vacuum environment can also increase the wetting area.

Shenzhen JJY Industrial Technology Co., Ltd. is a company15As a manufacturer specializing in the research and development and customization of solder paste, lead-free solder paste and leaded solder paste for many years, if you want to learn more about solder paste, please continue to follow the online message of JJY Solder Paste Factory to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account