Dispensing solder pasteIt is a kind of solder paste filled in a syringe, through which the dispensing needle comes into contact with the pad and releases the solder paste on the substrate pad. Considering the different processing methods, dispensing solder paste cannot be packed in cans like printing solder paste, but in syringes. Therefore, some people call it syringe solder paste. However, solder paste packaged in a syringe is not necessarily dispensing solder paste. Dispensing solder paste is not limited to "dots". By optimizing the dispensing process, it can achieve the coating of solder paste patterns in the form of dots, lines, and graphs. The following is an explanation from a solder paste manufacturer:

Classification of dispensing solder paste:

By alloy classification: Generally divided intoSAC305SeriesSnBiAgSeriesAuSnSeriesBiXSeries, etc.

Classified by particle size distribution: Generally, it is divided intoT2-T10Different product models;

Classified by melting point (or reflux temperature) : Generally, it is divided into high-temperature dispensing solder paste, medium-temperature dispensing solder paste, and low-temperature dispensing solder paste.

By flux classification: Generally, it is divided into0Halogen, halogen-free and halogen-containing dispensing solder pastes;

According to the post-weld cleaning property, it is generally divided into water-washed, no-wash and solvent-washed dispensing solder paste.

By consistency: Generally, it is divided into high-viscosity, medium-viscosity and low-viscosity dispensing solder paste.

By carrier: Generally, it is divided into rosin resin-based and epoxy resin-based solder paste.

Divide according to other requirements.

Selection of dispensing solder paste:

The solder paste has excellent sphericity, a smooth and clean material surface, and good rheological properties. Considering that the dispensing solder paste needs to be coated onto the pad through the dispensing needle, it is necessary that the dispensing solder paste can ensure good flow performance during a long dispensing process and must not clog the dispensing needle. Not only that, the dispensing solder paste should not draw wires or stick glue during operation, and it should also have a certain shape retention ability.

The reflux curve graph of dispensing solder paste

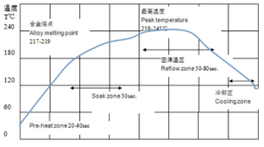

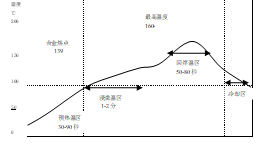

The reflux curve of dispensing solder paste is not much different from that of printing solder paste. A typical reflux curve is shown in the following figure:

SAC305Reflow curve of dispensing solder paste

SnBiAg0.4Reflow curve of dispensing solder paste

In recent years, with the adjustment of the alloy particle size distribution in solder paste and the change of flux composition, the reflow curve Settings of different solder pastes will be comprehensively optimized to achieve the best soldering process results.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account