Low solid content no-cleaning fluxLSFIt is a new type of flux developed in recent years to ban Freon and protect the ozone layer of the atmosphere. It has the advantages of low solid content, halogen-free, less ionic residue, high insulation resistance, no need for cleaning and good weldability. This is mainly due to people's advantages and demands for environmental protection. This flux is being applied more and more widely at home and abroad. today,Solder paste manufacturerWe will introduce to you the no-clean flux with low solid content.

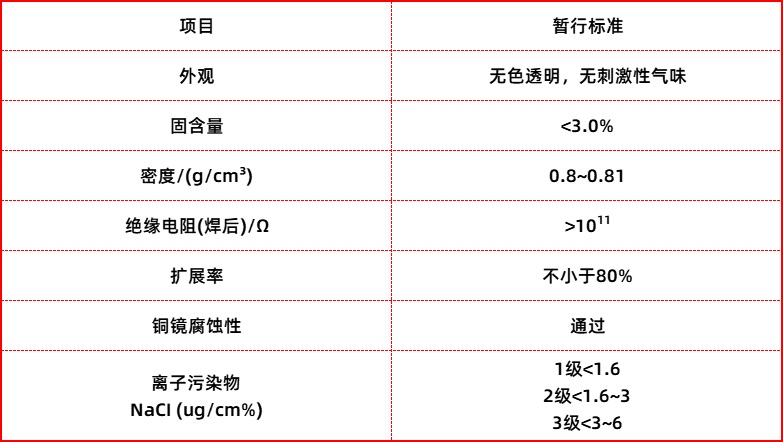

Nowadays, there are also fixed technical indicators for low-solid-content no-cleaning fluxes. For detailed information, please refer to the following figure:

Low solid content no-cleaning flux standard

Generally speaking, only fluxes that meet the above standards can be regarded as true "no-clean fluxes". They can also be widely used in the soldering of high-end digital products, and no further treatment is required after soldering. However, there are still some manufacturers on the market that meet the insulation resistance standards10ΩFluxes of this type are collectively referred to as "no-cleaning fluxes". Even though all these fluxes have the advantage of being no-cleaning, because they do not pay much attention to the solid content and the ion content of residues, their solid content is relatively high(The solid content is10%~16%)It is only applicable to common level digital products.

The components of no-clean flux

No-clean flux contains components such as active agents and solvents. These functional additives include corrosion inhibitors, matting agents and foaming agents, etc.

1Active agent

The active agent required for no-clean flux is much higher than that for common flux. This is mainly due to its low solid content and relatively less active substances. To achieve exactly the same welding effect, the activity of the active agent needs to be stronger.

2Other additives

It mainly includes wetting agents, corrosion inhibitors, foaming agents and antioxidants. The functional principle is exactly the same as that of additives in other fluxes. However, when coordinating, great attention must be paid to the overall coordination and quantity.

3Solvent

Resin-based no-clean flux contains a large amount of organic solvents(97%)Generally, most of the solvents are eliminated during the preheating stage of welding, and only a small amount of solvents are kept to evaporate completely in the welding area. Therefore, there should not be too much high-boiling-point solvent in the flux;However, if there is no high-boiling-point solvent at all, it will affect the heat conduction and prevent secondary oxidation after welding. Therefore, the solvents in rosin type no-clean flux still use mixed organic solvents.

The characteristics of solder paste for operating no-cleaning flux

1It has good solderability.

2It is non-toxic, has a low odor, a reliable operation process, generates little smoke during welding, and does not cause environmental pollution.

3There is very little residual debris after welding.PCBThe surface is dry, non-sticky, light in color, and has the ability for online testing.

4The residual debris after welding is non-corrosive, has good moisture resistance, and meets the insulation resistance value on the surface as specified.

5It is quite suitable for a variety of coating processes such as dip welding, foaming, spraying or misting, and coating.

6It has a very long storage period, usually more than one year, and has strong stability.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account