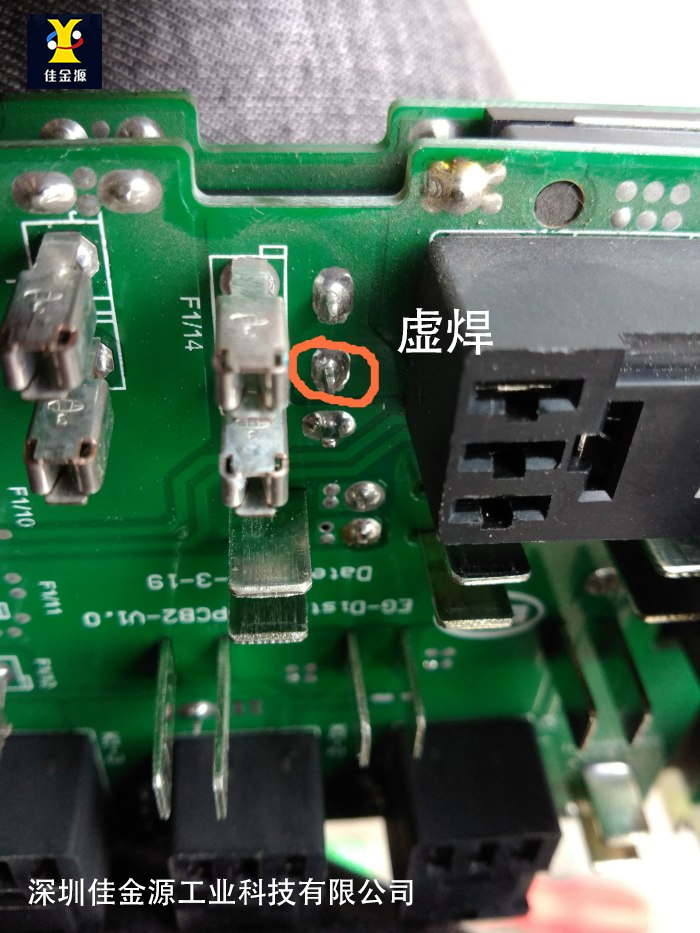

PCBASolder pasteProcessing refers to welding and assembling electronic components andPCBThe process of printing circuits plays a crucial role in ensuring the quality and stability of electronic products. False soldering refers to the situation during the soldering process where the solder does not fully wet the pad or pad, resulting in only partial contact between the pad and the pad. False soldering can lead to poor contact at the solder joints, thereby affecting the reliability of current transmission and signal transmission. Below, Shenzhen JJY Solder Paste Manufacturer will introduce it to you:

The hazards of false welding are mainly reflected in the following aspects:

Poor current transmission: False soldering can lead to poor contact at the solder joints. When current passes through, resistance is generated, thereby affecting the stability and efficiency of the circuit.

Unreliable signal transmission: False soldering can lead to signal attenuation and interference, affecting the normal operation of the equipment, and may even cause misoperation or damage.

Causing short circuits and open circuits: After a false solder joint, the contact between the solder pad and the solder foot is not firm, which can easily lead to short circuits or open circuits, thereby causingPCBAThe board is damaged.

Shortened product lifespan: False soldering can cause unstable contact at the solder joints. Over time, the solder joints may become loose or fall off, further affecting the reliability and lifespan of the product.

Regarding the problem of false soldering,PCBAProcessing manufacturers usually adopt the following several methods for improvement:

Optimize the welding process: Adjust the welding temperature, time and pressure to ensure that the solder can fully wet the pads and pins during the welding process, thereby improving the welding quality.

Use appropriate solder: Select solder materials suitable for the soldering process, ensuring their viscosity and wettability to reduce the occurrence of false soldering.

Strengthen welding management: Strictly abide by the operation norms during the welding process, enhance welding training and management, and improve the welding technical level and quality awareness of operators.

False soldering refers to the situation where the solder does not wet the surface of the pad or pad during the soldering process, but instead forms a film with the surrounding air. It seems that the welding is intact, but in fact, an effective connection with the weld point has not been achieved. False welding is a concealed quality issue that is difficult to identify by appearance.

The main reasons for false soldering are: the viscosity of the solder is too low, making it difficult for the solder to wet, the soldering temperature is too high or the soldering time is too long, and there are dust and other impurities around the soldering area, etc.

The hazards of false welding are mainly reflected in the following aspects:

Unstable product performance: There are quality issues with the weld points after false welding, which leads to unstable product performance and may cause problems such as disconnection and malfunction during use.

Signal transmission interruption: False welding can cause the solder joint not to be truly connected, which will lead to signal transmission interruption and affect the normal operation of the equipment.

Shortened product lifespan: False welding can cause the solder joints to loosen. Over time, the solder joints may fall off, resulting in a shortened product lifespan.

PCBAIntroduction to Processing false Welding and fake welding

Regarding the problem of false weldingPCBAProcessing manufacturers usually adopt the following several methods for improvement:

Optimize the welding process: Select the welding temperature and time reasonably to ensure that the solder can fully wet the surface of the pads and pins, thereby improving the welding quality.

Strengthen environmental control: Keep the welding area clean and reduce the impact of debris on welding quality.

Enhance the technical proficiency of operators: Strengthen the training and management of operators to improve their awareness and ability to handle false welding issues.

False soldering and false soldering arePCBACommon quality problems in processing are crucial for ensuring the quality and performance of electronic products.PCBAProcessing manufacturers need to attach importance to and strengthen the control and improvement of false soldering and false welding problems to enhance the reliability and stability of products. Only on the premise of ensuring the welding quality can high-quality electronic products be produced.

As a solder paste manufacturer with sixteen years of experience, JJY has been committed to the research, development, production and sales of solder paste. Our product quality is stable, with no solder connection, no false soldering, and no monument erection. Residual Wuxi beads, bright and full solder joints, firm welding, and excellent electrical conductivity. If you have any needs, please feel free to contact us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account