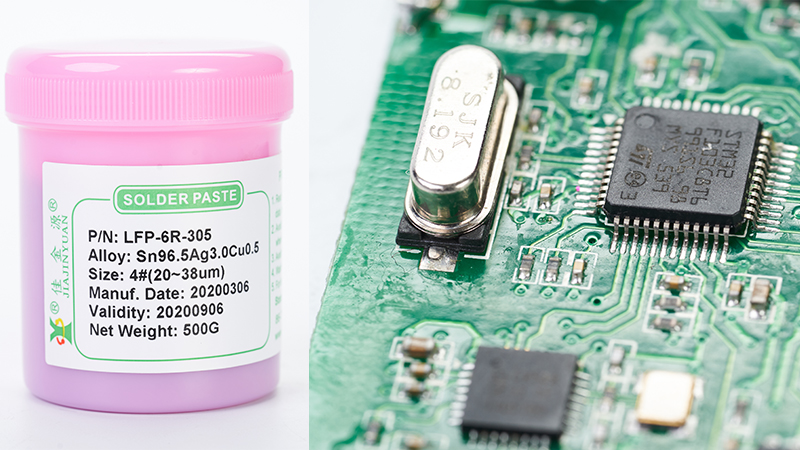

SMTSurface mount technology (SMT) factories select the appropriate ones based on different products and processesSolder pasteIt can effectively improve the production quality. There are usually many devices in the production site of a factory, and the equipment used in the production line also has a very high level of safety. Is that enough? This is definitely not enough. We must learn traditional safety knowledge and cannot ignore them. Below, Shenzhen JJY Solder Paste Manufacturer will briefly introduce to you the common methods for choosing solder paste:

1Consider the number of reflow ovens andPCBAnd the temperature requirements of components:High, medium and low temperature solder paste.

2According toPCBThe cleanliness requirements and different cleaning process options after reflow soldering:When using the no-cleaning process, choose no-cleaning solder paste that is free of halogens and strong corrosive compounds. When using the solvent cleaning process, choose solvent cleaning solder paste. When using the water cleaning process, water-soluble solder paste should be selected.BGAandCSPGenerally, high-quality no-clean silver-containing solder paste needs to be selected.

3According toPCBThe activity of the paste should be selected based on the storage time of the components and the degree of surface oxidation:Generally adoptedKJRMAGrade-High-reliability products, aerospace products and military products can be selectedRGrade;-PCBComponents that have been stored for a long time and have severe surface oxidation should be adoptedraPost-weld cleaning

4The particle size of the alloy powder is based onSMTThe assembly density(Is there a narrow spacing?)Come and choose. The particle sizes of alloy powders commonly used in solder pastes can be classified as4Particle size grade(2Number,3Number,4Number,5Followers)It is generally selected when the spacing is relatively narrow20-45um;

5Select the viscosity of the solder paste based on the solder paste application process and assembly density. High-density printing requires high viscosity, while drop coating requires low viscosity.

6According to environmental protection requirements, lead-free solder paste should not be used in lead-free processes.

JJY Solder Paste Manufacturer mainly produces and supplies lead-free solder paste.SMTSurface mount solder pasteLEDSolder paste, lead-free solder wire, wave soldering rods, red glue and other solder solders. For more knowledge about electronic soldering, please contact us. Welcome to interact with us.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account