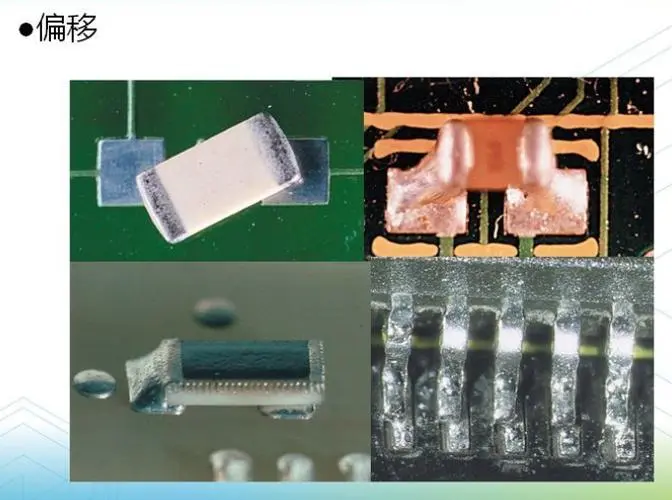

SMTProcessing, as a key link in modern electronic manufacturing, often encounters some problems in practical operation. This article will explore it in depthSMTThe problem of offset and providing corresponding solutions can be completed more smoothlySMTSurface mount Technology (SMT) processing, below is Shenzhen JJYSolder paste manufacturerLet me explain it to everyone:

First of all, patch offset isSMTOne major challenge in processing. Due to factors such as temperature and vibration, the patch is soldered toPCBAt this time, offset may occur, resulting in a decrease in welding accuracy. To solve this problem, we can take the following measures:

1Use high-precision positioning tools to ensure that the patches can be accurately placedPCBUp.

2During the soldering process, strictly control the temperature and time to reduce the risk of patch offset.

3Use adhesive or glue to fix the patch and ensure it remains stable throughout the soldering process.

Secondly, poor welding quality is also a problemSMTCommon problems in processing. Poor welding may lead to circuit faults and affect product quality. To improve the welding quality, we can:

1Ensure that the welding equipment operates well, such as regularly cleaning the welding joints and maintaining an appropriate heating temperature.

2Select appropriate welding materials and techniques, such as choosing suitable solder wires and welding head shapes.

3Before welding, carry out strict inspection and testing to ensure that each welding point meets the requirements.

Finally, so is the damage to electronic componentsSMTA major hidden danger in processing. Improper operation or external factors may both lead to component damage. To reduce the risk of damage to electronic components, we can:

1During the operation process, take anti-static measures, such as wearing anti-static gloves and using anti-static tools.

2When storing and handling electronic components, avoid drastic changes in temperature and humidity.

3Choose suppliers with good reputation and quality guarantee to ensure the reliable quality of components.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account