20Century90Over the years, with the continuous development of electronic technology,ICThe degree of integration is also constantly improving, on integrated circuitsI/OThe number of pins and pages is also constantly increasing. All kinds of factorsICEncapsulation has put forward higher requirements. Meanwhile, in order to meet the requirements of the development of electronic products towards miniaturization and precision,BGAPackaging was born and put into production. The following is JJYSolder paste manufacturerLet me give you a brief introductionBGASome information:

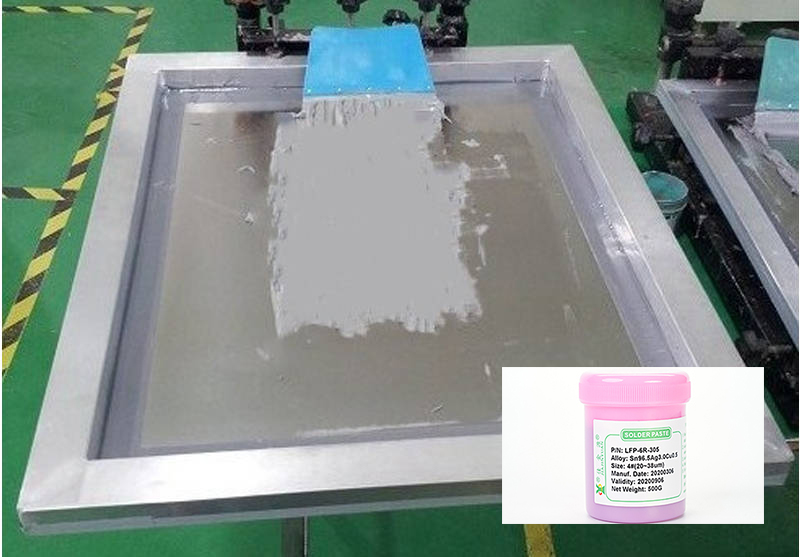

1. Steel mesh

In realitySMTThe thickness of steel mesh in surface mount technology (SMT) processing is generally0.15mmBut inBGAIn the welding processing of the device0.15mmThick steel mesh is very likely to cause tinning. According to Pet Precision's surface assembly production experience, the thickness is0.12mmFor the steel meshBGAIt is particularly suitable for the device, and at the same time, the opening area of the steel mesh can also be appropriately increased.

Ii. Solder paste

BGAThe pin spacing of the device is relatively small, so the solder paste used also requires small metal particles. Excessively large metal particles may causeSMTThe phenomenon of continuous tin formation occurred during processing.

Iii. Welding Temperature Setting

inSMTIn the surface mount technology (SMT) processing, reflow soldering is generally usedBGABefore soldering the packaged devices, it is necessary to set the temperature of each area according to the processing requirements and use a thermocouple probe to test the temperature near the solder joint.

Iv. Post-welding inspection

inSMTIt should be correct after processingBGAThe packaged devices undergo strict inspection to avoid some surface mount defects.

V.BGAAdvantages of packaging:

1The assembly yield rate has increased;

2Improvement of electric heating performance;

3The volume decreases and the mass decreases;

4The parasitic parameters decrease;

5Small signal transmission delay;

6Increase in usage frequency;

7The product has high reliability.

Vi.BGADisadvantages of packaging:

1The post-welding inspection needs to be passedXRay

2The production cost of electronics has increased;

3Increase in repair costs;

Due to its packaging characteristics,BGAinSMTIt is rather difficult in surface mount soldering, and the soldering defects and repairs are also rather challenging.

Shenzhen JJY Industrial Technology Co., Ltd. mainly engages in the production and operation of:SMTSolder paste manufacturers of solder paste, syringe solder paste, lead-free solder wire, wave soldering bar, automatic soldering wire, etc.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account