inSMTIn surface mount technology (SMT), different soldering processes often occur, so we need to choose different solder pastes. Then, how can we determine which soldering process is differentSolder pasteAnd? Today, Shenzhen JJY Solder Paste Manufacturer will explain to you aboutSMTHow to choose and use solder paste in surface mount technology (SMT) processing:

First, based on the value and application of the product itself,PCBAPrecision of surface mount processing componentsPCBSelect solder paste based on the actual situation such as the storage time of components, the degree of surface oxidation, and the process conditions of the production line. Different situations require different solder pastes. The composition, purity and oxygen content of solder paste alloy powder, particle shape and size, as well as the composition and properties of flux are the key factors determining the characteristics of solder paste and the quality of solder joints.

Second, according to the surface mount technology of the product,PCBSelect the solder paste alloy composition based on the specific conditions of the board and components.

1GeneralPCBThe adoption of lead and tin plating on solder pads63Sn/37Pb.

2Palladium gold or palladium-silver thick film ends and pins with poor solderabilitySMTFor surface mount processing of components with high requirements for solder joint qualityPCBAdopt62Sn/36Pb/2Ag.

3Of gold-plated padsPCBGenerally, do not choose solder paste containing silver(Gold and tin in the solder form covalent compounds between gold and tinAuSn4The gold content in the solder exceeds3%It will make the solder joint brittle,The thickness of the gold layer used for welding should≤1um"

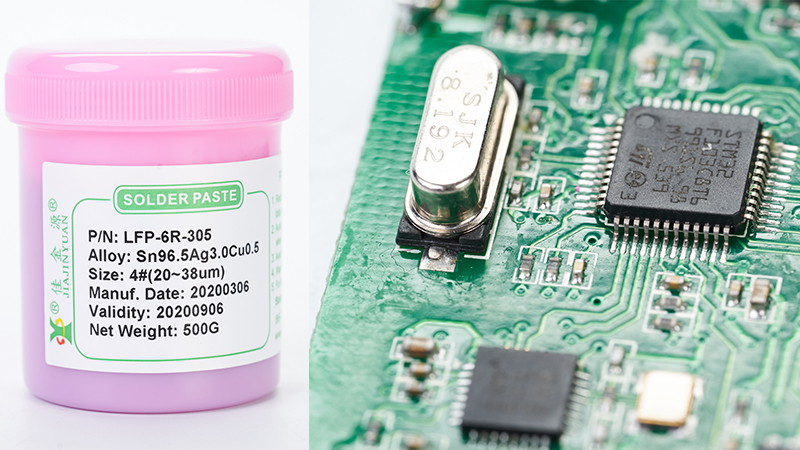

4Lead-free processes are generally chosenSn-Ag-CuAlloy solder.

Iii. Choose whether to adopt no-cleaning based on the product's cleanliness requirements

1For the no-cleaning process, solder paste that does not contain halogens or other weakly corrosive compounds should be selected.

2Solder paste for high-reliability products, aerospace and military products, high-precision and low-signal instruments and meters, as well as medical equipment related to life safety should be cleaned with water or solvents,It must be cleaned thoroughly after welding.

Iv.BGAandQFNGenerally, high-quality solder paste that does not require cleaning is needed.

V. When welding thermosensitive components,Low-melting-point solder paste containing bismuth should be selected.

Vi. According toSMTThe pin density of surface mount processing components (whether there is a narrow pitch or not))Select the particle size of the alloy powder.SMTThe pin spacing of surface mount processing components is also one of the important factors in choosing the particle size of alloy powder. The most commonly used one is3Followers(25~45um),When the spacing is narrower, the particle diameter is generally selected to be40umThe following alloy powder particles.

The above content is shared with you by Shenzhen JJY Industrial Technology Co., LTDSMTThe relevant content about how to choose solder paste in surface mount technology (SMT) processing is hoped to be helpful to you. If you want to know more about solder paste andSMTKnowledge of surface mount technology (SMT) processing. Welcome to leave a message and interact with us!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account