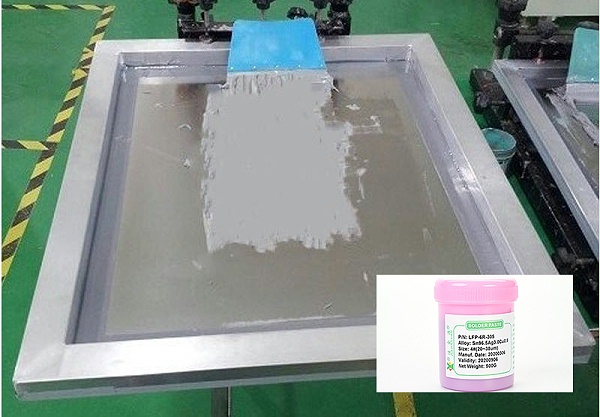

insmtIn surface mount technology (SMT) processingSolder pastePrinting is a crucial process that directly affects the quality of solder joints and the performance of electronic components. When solder paste printing, sometimes the problem of steel mesh blockage is encountered, which will affect the transfer and distribution of solder paste, thereby leading to soldering defects. So, what are the reasons for the steel mesh being blocked? Today, JJY Solder Paste Manufacturer will analyze it together with everyone:

The reasons for the steel mesh being blocked:

1The steel mesh was not cleaned thoroughly. If there is dust or debris on the steel mesh, it will stick to the solder paste, forming "clumps" and causing the steel mesh to be blocked. Therefore, before using the steel mesh, it should be cleaned with special cleaning agents and tools to keep the steel mesh clean and dry.

2The opening design of the steel mesh is unreasonable. If the openings of the steel mesh are too small or there are burrs on the edges of the steel mesh, it will cause the solder paste to not flow down, thus resulting in mesh blockage. Generally speaking, the openings of the steel mesh should be designed based on the size of the components and the particle size of the solder paste to ensure that the solder paste can fully pass through and cover the solder pads. Meanwhile, the edges of the steel mesh should be smooth without burrs to avoid scratching the solder paste or affecting its flow.

3The temperature and humidity of the usage environment are not suitable. Temperature and humidity can affect the viscosity and fluidity of solder paste, thereby influencing its delamination. If the temperature is too high, the flux will evaporate quickly, causing the solder paste to dry out and harden. If the humidity is too high, the solder paste will absorb moisture, causing it to become thinner and softer. All these will cause the solder paste to not pass through the steel mesh fully and be prone to sticking to the steel mesh. Therefore, when using solder paste, the temperature and humidity of the usage environment should be controlled within an appropriate range.

4The material, pressure, speed and other parameters of the scraper are not appropriate. The scraper is a tool used to scrape solder paste off the steel mesh, and it plays an important role in the transfer and distribution of solder paste. If the parameters such as the material, pressure and speed of the scraper are not appropriate, it will cause the solder paste to not pass through the steel mesh evenly and be prone to residue on the steel mesh. Therefore, when using a scraper, adjustments should be made according to the characteristics of the solder paste and the steel mesh to ensure that the scraper can effectively scrape the solder paste off the steel mesh.

5The pressure of the pressure plate and the time of plate removal are inappropriate. The pressure of the pressure plate refers to the pressure that tightly adheres the circuit board to the steel mesh, which determines whether the solder paste can be evenly transferred to the circuit board. The de-board time refers to the time it takes to separate the circuit board from the steel mesh, which determines whether the solder paste can be completely separated from the steel mesh. If the pressure of the pressure plate is too high or too low, it will lead to an uneven distribution of solder paste. If the de-board time is too long or too short, it will lead to the residue or breakage of solder paste. Therefore, when using the pressure plate and removing the plate, adjustments should be made according to the characteristics of the solder paste and the steel mesh to ensure that the solder paste can be smoothly removed from the steel mesh.

As a 15-year-old veteran solder paste manufacturer, JJY has been dedicated to the research and development and production of solder paste for many years. The quality of the solder paste is stable, without solder bonding, false soldering or establishing a reputation. No residue, Wuxi beads, bright and full solder joints, firm solder joints, and excellent electrical conductivity. If you have any needs, please feel free to contact us.