Lead-free solder pasteThe differences in composition, the melting point standard of solder paste, what do we generally consider flux to be? What is flux paste? I believe many friends may still be unclear about the differences between them. So now, I can explain their concepts and the connections between them to everyone:

The difference in point temperature of lead-free solder paste

Standard deviation of melting point of leaded solder paste183℃The standard deviation of the melting point of high-temperature flux paste without heavy metals is217℃Therefore The welding temperature of electric welding without heavy metals is higher than that with lead, and the higher value of the welding temperature of lead-free electric welding should be200-205℃The highest point temperature is235℃.

Flux: It is usually a mixture mainly composed of rosin and serves as an auxiliary material to ensure the smooth progress of the welding process. Welding is the main process in electronic assembly. Flux is an auxiliary material used in welding. The main function of flux is to remove the oxides on the surface of solder and the base material to be soldered, so that the metal surface reaches the necessary cleanliness. It prevents the re-oxidation of the surface during soldering, reduces the surface tension of the solder, and improves the soldering performance. The quality of the flux directly affects the quality of electronic products.

Flux paste: A paste-like chemical substance that plays two main roles in the welding process: "removing oxides" and "reducing the surface tension of the material to be welded". It is widely applied in watch instruments, precision components, medical devices, stainless steel handicrafts, tableware, mobile communication, digital products, air conditioning and refrigerator refrigeration equipment, eyewear, knives, car radiators and all kinds of other productsPCBBoard andBGABrazing of tin balls.

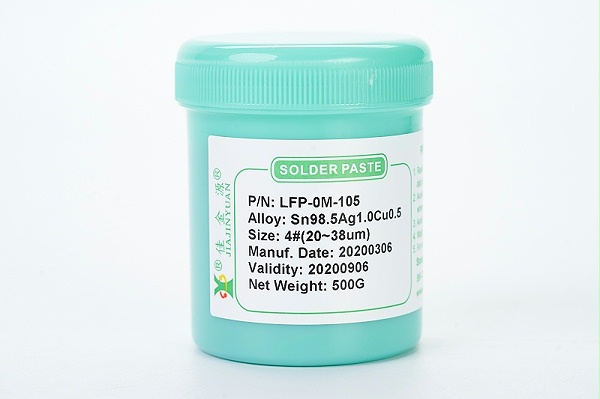

But there must be a difference in others' perception. Generally, lead-free solder paste is emerald green, while leaded solder paste is milky white. Naturally, due to the difference in composition, their melting points, actual welding effects, and spot welding color all vary.

The composition of lead-tin paste depends on the type of tin. There are many different alloy compositions of lead-tin. In lead-tin alloys, tin and lead are the key components. In ultra-low temperature lead-tin alloys, bismuth is also a key component. Apart from this kind, tin-molded alloys will all have a slight difference.

deepShenzhen JJY has carried out mutually beneficial cooperation with electronic raw material producers. At the same time, it also produces solder wire, solder bar, solder paste and flux paste for other enterprises. With a rich variety of successful cases in the research and development of chemical raw materials, our overall strength has created a sales market that is of high quality and honest and trustworthy.