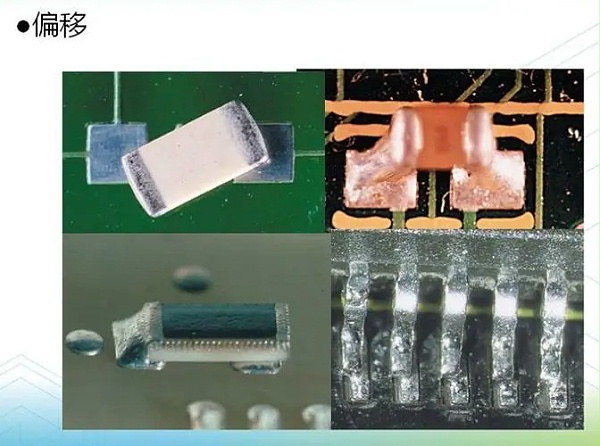

inSMTThe correct soldering of components in the surface mount technology (SMT) processing in factories directly affects the soldering quality, and component offset is an important part of the soldering quality. How can we prevent the phenomenon of component offset in surface mount technology (SMT) processing? Below is Shenzhen JJYSolder paste manufacturerLet me give you a brief introduction:

1Strictly calibrate the positioning coordinates to ensure the accuracy of component mounting.

2Using high-quality solder paste with high viscosity can increase the performance of componentsSMTMounting pressure to enhance adhesion.

3Select the appropriate solder paste to prevent the occurrence of solder paste collapse and ensure that the solder paste contains an appropriate amount of flux.

4Adjust the rotational speeds of the fan and the motor.

In fact,SMTIn the reflow soldering process of surface mount technology (SMT) processing, apart from component offset, there are also many other possible defects, such as side tilting and other undesirable phenomena. However, all these problems can be solved. Start by doing a good job in the circuit board design. It's excellentPCBMake the plates to the person in chargeSMTIn the surface mount technology (SMT) processing, every step, from components to solder paste and processes, should be done well to fundamentally improve the quality of our reflow soldering and prevent component deviation.

The above is aboutSMTKnowledge about the offset phenomenon of components in factories, I hope it will be helpful to everyone! For more knowledge about solder paste, please keep following JJY lead-free solder Paste Manufacturer and leave a message online to interact with us.