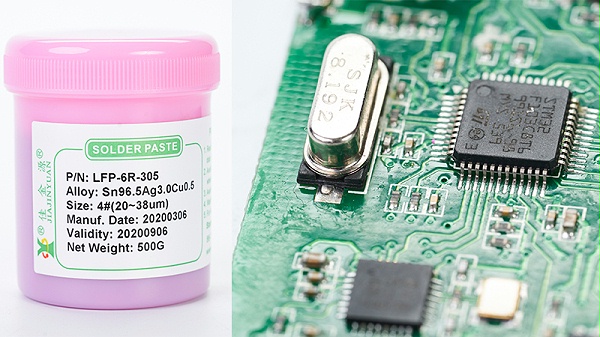

SMTDuring the production process of surface mount technology (SMT) processing, many different processing defect phenomena may occur. Different environments and operation methods can lead to different processing defects.SMTSurface mount technology (SMT) is also a precision processing method. It is normal for some problems to occur. What needs to be done is to control the quality well during the processing and solve all these possible problemsSolder pasteThe defect isSMTAmong the processing defects, solder paste defects are relatively common. The processing links involved are quite numerous, for instanceBOMandGerberComponent procurement, storage and access control, solder paste printingSPISolder paste testing, reflow soldering, etc. Below, Shenzhen JJY Solder Paste Manufacturer will briefly introduce to you how to prevent the occurrence of solder paste defects:

inSMTDuring the surface mount technology (SMT) processing, the requirements in the quality management system must be strictly followed.

1. In large quantitiesSMTIn surface mount technology (SMT) processing, the processing cycle is usually quite long. At this time, there may be factors such as dry solder paste on the steel wire mesh, or the holes in the template and the circuit board not being aligned properly, which can easily lead to poor soldering. All these need to be dealt with promptly.

Second, fix the printing cycle in a specific pattern during the solder paste printing process. Make sure the template is located on the solder pad, which can ensure the cleanliness of the solder paste printing process. For micro templates,If damage occurs between the thin pins due to the bending of the template cross-section,It may lead to printing defects and short circuits.

Iii.SMTAfter printing the solder paste in the turnkey process, the improperly printed boards should be immediately immersed in the soaking solvent, as the solder paste is easy to remove before it dries.

Fourth, to prevent solder paste and other contaminants from remaining on the surface of the circuit board, a clean cloth can be used to wipe it. After soaking, scrub with a gentle spray and it is best to dry with a hot air blower. If a horizontal template cleaner is used, the cleaning side should face down to allow the solder paste to fall off the template.

JJY Solder Paste Factory produces a wide range of solder paste products, including lead-free solder paste, halogen-free solder paste, silver-containing lead solder paste, syringe solder paste, nickel-plated environmentally friendly solder wire, solder bar, etc. We can provide technical support. If you have any needs or technical questions regarding soldering, please feel free to leave a message online to interact with us!