Heating is carried out using laser as the heat sourceSolder pasteMelting laser welding, its main feature is that the efficiency of the laser can be fully converted to complete the entire process of rapid heating and soldering in some or fine areas.Solder paste manufacturerCompared with the traditional laser soldering methodSMTWelding methods have irreplaceable advantages.

When using a traditional reflow soldering oven, the soldering temperature required for electronic components will rise rapidly, thereby causing the components to overheat. Some thin and heat-sensitive electronic components may be damaged.

In addition, the excessively long heating time of the overall heating method can easily lead to the thickening of the crystals of the welded metal materials and the penetration of chemical substances between the metal materials, reducing the fatigue service life of spot welding. Laser soldering is a reflow soldering method with partial heating, which can effectively avoid the occurrence of the aforementioned problems.

The laser line can focus on a small black spot. The laser kinetic energy is confined within a small black spot range, which can complete the heating of the welding area. The thermal shock damage to heat-sensitive electronic components can be avoided.

The input kinetic energy of the welding area can be precisely controlled, which is crucial for the quality reliability of the surface assembly welding disc connection head.

Laser welding can only heat the welding area, while the base steel plates between the wires are not heated or the temperature increase is much lower than that of the welding area, which hinders the connection of solder paste between the wires. Therefore, the occurrence of bridging defects can be reasonably avoided.

LaserSolder pasteThe entire welding process is divided into two steps: After applying solder paste in the basic way, welding is carried out by laser. The laser solder paste needs to be heated, and the spot welding is also heated. In the future, the commonly used laser solder paste for welding is completely melted, and the solder paste fully wets the solder layer, then a weld is produced.

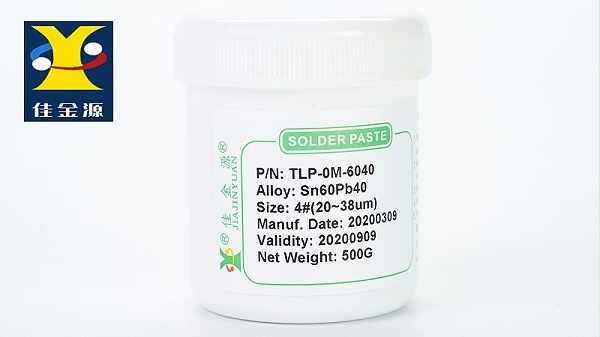

If you have any other questions about solder paste, partners are welcome to come and consultShenzhen Jiajin Qianyuan Industrial Technology Co., LTDLet's learn and grow together!