inSMTSolder pasteIn the process of surface mount technology (SMT) assembly, many people are puzzled. Besides conducting experimental verification and printing the solder paste on the circuit board, and then verifying the quality of the soldering through reflow soldering after SMT assembly, what other methods can be used to verify the quality of the solder paste in advance?That is to say, before the pre-placement, the quality of the solder paste is tested through some standards. Because the quality of solder paste will directly affect the entire connectivity of electronic products after soldering, not only the structural connection but also the electrical performance conduction. If the above-mentioned test verification method is used, such as reflow soldering, not only will time be wasted, but also the differences among different circuit boards of the same batch will be relatively large. Is there any way to conduct tests before the surface mount technology or solder paste manufacturers deliver the materials? Today, Shenzhen JJY Solder Paste Manufacturer will explain how to test incoming solder paste to help iqcThe department makes judgments in advance.

Steps for testing the quality of solder paste:

1For solder powder testing, a high-magnification microscope can be used to measure the particle size of the tin powder to check the distribution of the tin powder particles. If the particle size of the metallic tin powder is relatively round and the sphericity is good, it indicates that the quality of this type of solder paste solder powder is relatively good and will not affect the quality of surface mount printing on the screen.

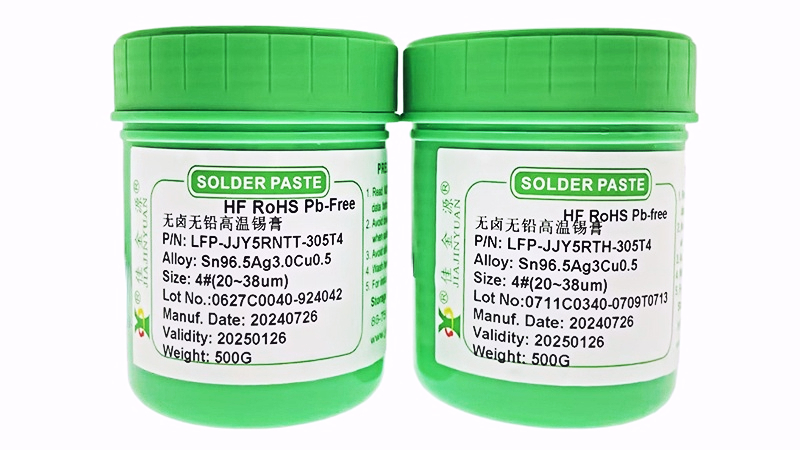

2The chemical elements in solder paste are measured using an atomic absorption spectrometer. Usually, the detection items are harmful metal elements such as lead, mercury and cadmium If the solder paste is halogen-free, it is also necessary to check in advance whether the halogen content in the solder paste meets the standard.

3Viscosity test: The viscosity of solder paste will greatly affect the printability on the screen. If the viscosity of a solder paste is high, the sagging performance will be greatly improved, but the printability will be poor, which may affect the demolding effect and may stick to the stainless steel screen, resulting in poor printing.

4Steel mesh printability test, usagesmtPrinting solder paste on steel mesh is an indispensable step in the surface mount technology (SMT) soldering process. Therefore, it is essential for a solder paste to have good printability. ThereforeIQ CThe department can take a small amount of solder paste for printability testing to verify whether the printability of the steel mesh of this solder paste is good.

5The solderability of the solder hook is tested. The solderability of the solder paste can be divided into wettability and solderability. This function is mainly to test whether the solder paste will dry out. If it does not dry out, it is necessary to check whether the connection strength after soldering meets the specified requirements. This step of testing for quality can be carried out using discarded circuit boards and disassembled electronic components.

6To check if the solder joints are full and shiny, this inspection step can be carried out by pasting solder paste on the glass and performing flow soldering. After the soldering is completed, it can be observed with the naked eye to see if the solder joints are shiny. It is also possible to see from the glass whether there is a lot of residue after solder paste soldering.

Through the above steps, we can basically judge the quality of a solder paste either visually or based on the data. Whether this solder paste is lead-containing, lead-free or silver-containing, both the surface mount technology (SMT) factory and the electronics factory can summarize and organize the data from each test into a table. The quality of the solder paste is verified by analyzing the results of each test. The above content is explained by Shenzhen JJY Solder Paste Manufacturer. Welcome to leave a message online and interact with us!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account