Solder paste andSMTPatchRed glueWhat are the differences? Generally speaking, red glue is processed by automatic dispensing machines and can be used for circuit boards of fewer grades, while solder paste is processed by heat transfer printing technology and is mostly used for circuit boards with self-adhesive labels. From the perspective of quality, compared with solder paste, red glue is more susceptible to weather conditions, has a higher rate of non-conformity after soldering, and is more likely to cause component dropping and missed soldering. From the perspective of practical application effects, red glue isSMTSurface mount type can It has a fixed actual effect but does not conduct electricity;Solder paste not only remains stationary but also has a good conductive effect.

Red glue belongs to polyethylene chemical substances,Unlike solder paste, it will dry and solidify when exposed to heat,Its freezing point is approximately at a temperature150℃,At this time,The red glue gradually changed from a mud-like substance to a solid state immediately.The characteristics of red glue:Red glue has viscosity fluidity,Temperature characteristics,Wetting characteristics, etc..Based on this characteristic of red glue,Therefore, in the production and processing,The goal of using red glue is to firmly adhere the partsPCBSurface,Avoid It was exposed. Solder paste isSMTIt is an indispensable raw material,After this type of raw material has been processed and melted,Be able to.SMTThe parts are welded by electric weldingPCBOn Tongbo,It serves to connect and conduct electricity.The function of this type of material is similar to that of the solder bars and solder water used in wave soldering that are often encountered. From a technical perspective, the red glue is processed by an automatic dispensing machine, and the available grades are fewpcbApplication of circuit boards;The solder paste used is the through-the-oven printing technology, which is mostly used for one-time self-adhesive label paperpcbCircuit board. From the perspective of quality, compared with solder paste, red glue is more susceptible to weather conditions, has a higher rate of non-conformity after soldering, and is more likely to cause component dropping and missed soldering. From the perspective of practical application effects, red glue isSMTThe surface mount type can have a fixed effect, but it is not conductive;Solder paste not only remains stationary but also has a good heat conduction effect.

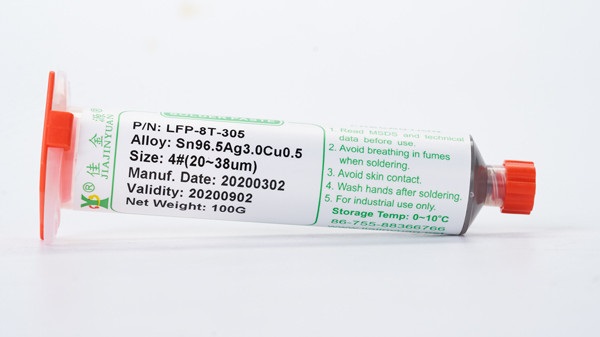

The above isRed glueThe difference from solder paste is that red glue belongs to polymeric chemical substances,The difference from solder paste is that it will dry and solidify after being heated,AccompaniedSMTThe development trend of processing technology, andLEDThe development of the industrial chain has led to an increasing demand for solder paste. Here, JJY solder Paste Manufacturer will explain some common knowledge about low-temperature solder paste to our partners:

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account