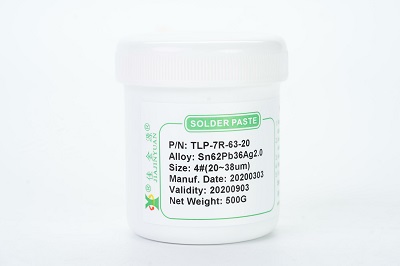

Leaded solder paste is a type of solder paste that does not require cleaning. Special solder paste and spherical tin powder are adopted, with extremely low oxide content. It has excellent continuous printing performance; Less residue and good electrical conductivity; In addition, no-clean solder paste can offer different alloy compositions, different tin particle sizes and different metal contents to meet customers' requirements for different products and processes. The following is an explanation from the solder paste manufacturer:

Leaded solder paste can be adapted to different grades of soldering equipment and specific requirements. It does not need to achieve the soldering process in a nitrogen-filled environment. Within a wide range of reflow oven temperatures, it can demonstrate good soldering performance, using "heating up.---Both the "heat preservation type" and the "gradual heating type" furnace temperature setting forms are applicable. After the welding process, there is less residual debris, the color is very light and all have a relatively large insulation resistance, and they will not corrode eitherPCBIt can meet the specific requirements of no-wash;All of them are goodICTTest the performance and there will be no misjudgment;It remains in its original shape for several hours after printing, with basically no sagging and no deviation of the surface mount components. All of them have good welding performance and can demonstrate appropriate lubricity in different parts.

There is lead solder pasteBefore opening, the temperature of the solder paste must be raised to the ambient temperature for use(25±3℃)The recovery period is approximately3~4When the hours are up, no other heating method should be used. After warming up, thorough stirring is required. Manual stirring period3-5Minutes. The stirring period using the mixer is approximately1~3Minutes, depending on the type of blender.

After warming up and stirring evenly

1Prepare the solder paste2/3The amount should be added to the steel plate and kept generally within limit at all times1The solder paste of the can is measured on the steel plate;

2Depending on the production speed, the amount of solder paste on the steel plate should be replenished in small amounts and multiple times to maintain the product quality of the solder paste;

3Solder paste that has not been used on the same day should not be stored together with unused solder paste. Personally, it is recommended that solder paste be stored after opening24It will be used up within hours;

4After the solder paste is printed on the substrate, I personally suggest4-6The components are mounted within hours and reflow soldering is added to achieve the soldering process;

5If the wire change takes more than one hour, please scrape the solder paste off the steel plate and put it in the solder paste can for sealing before the wire change;

6To achieve the best welding process results, please control the indoor temperature at22-28℃HumidityRH40~60%;

7To wipe the substrate with printing errors, it is recommended to use ethanol.IPACleaning.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account