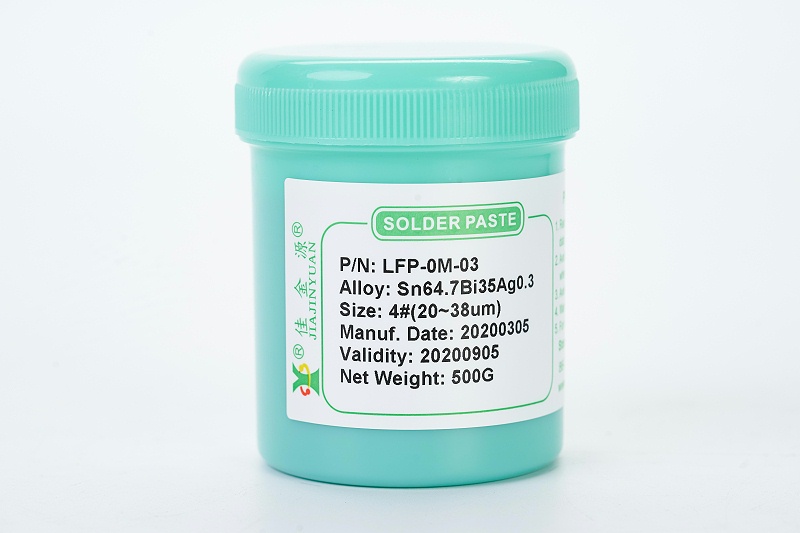

UsuallyLead-free solder pasteDuring the printing process, no one is quite clear about how long the lifespan is. It is usually made by using special flux and spherical tin powder with very little oxide content, and adopts a conformingRosin Mildly Activated Classification of Federal specificationThe required non-halogen activation system This solder paste isRMAFlux and tin powder particles are uniformly mixed. The solder paste contained in this product complies with the standards of the United StatesQQ-571As stipulated in itRMAType and passSGSTest compliantRoHSThe instructions require that the solder paste manufacturer explain it below:

This assessment process can be combined with the normal production process without the need for additional preparations or inputs. Proceed normallySMTSolder paste printing, observe the lead-free solder paste state on the steel mesh, and the shape of the solder paste after printing.SPITest the volume or coverage area of the solder paste, as well as the state of the solder paste on the steel mesh after long-term printing. There was once a case: After continuous printing for a period of time, the solder paste completely adhered to the squeegee, and there was no solder paste at all on the steel mesh. This situation would seriously affect the filling of the solder paste in the holes of the steel mesh, and its printing performance and working life would definitely not meet the normal production requirements.

Wettability test:The solder paste has been printedPCBOn the solder pad, following the normal reflux process, the solder paste melts and then wetsPCBSolder pad. Observe the area covered by the solder paste on the solder pad after printing. The area of the solder paste that melts and wets the solder pad. Theoretically, the larger the diffusion range, the better (relative to the solder paste). The solder must clearly wet the pad, and there should be no obvious non-wetting or de-wetting phenomena.

Tin ball test:Solder paste is printed on the surface of the ceramic plate as normalSMTThe reflux temperature melts the solder paste. Since there is no wetting between the ceramic substrate and the solder paste, after the solder paste melts, it will naturally form a metal ball under the action of the surface tension of the liquid. If the quality of the solder paste is poor, the molten metal cannot completely polymerize into individual solder balls but forms many small solder balls on the ceramic substrate. Such solder paste may lead to poor solder joint formation during use. Although there is an adequate amount of lead-free solder paste, it may be in a dispersed state due to the solder melting and inability to polymerize, resulting in insufficient final solder joint strength (insufficient solder). In the actual application process, the preparation of ceramic substrates is relatively difficult (they are not easy to find on site), and ordinary ones can be usedPCBThe alternative verification involves printing or applying solder paste on the solder mask film (green oil) and conducting reflow treatment. The evaluation effects of both methods are basically the same.

Adhesion forceTackiness"Test":Adhesion is the ability of solder paste to hold components in place. Components placed on solder paste will not move due to movement or stop changes on the track. If the adhesion force is insufficient, whenPCBWhen moving on the track with components or stopping the start-up, the components may move, causing misalignment and short circuit problems.

Components are usually mounted on test boards with printed solder paste orPCBOn the board, keep it for a period of time and conduct collision tests every two hours. letPCBWhen running on the track, at the normal stop position, there will be no displacement of components due to changes in motion. Of course, viscosity testing is also necessary, but most manufacturers do not have such testing instruments. Instead, it is necessary to have the viscosity tested by a third-party testing institution to see if it meets the specification requirements. In fact, the actual production conditions can also be directly adopted for testing, and the actual results can be used as the basis for evaluation. Viscosity value is an evaluation parameter. The most crucial thing is still to look at the actual application effect.

Flux residue detection:Whether flux residues need to be tested or not can be determined based on the actual situation. For consumer electronic products, no-clean solder paste or flux is used. Generally, flux residues are not tested unless there are special circumstances.

For the no-clean process, excessive flux residue may affect the inspection of appearance and reduceAOIOr visually inspect the effect to cause misjudgment and affect production efficiency. This is also one of the factors to consider when choosing no-clean solder paste.

Welding quality inspection:Whether a lead-free solder paste is suitable or not mainly depends on its soldering quality. All the evaluation elements mentioned above are aimed at achieving a good soldering effect. By statistically analyzing the soldering quality data after reflow, the defect problems generated are analyzed and it is determined whether they are related to the quality of solder paste. Problems such as poor wetting or short circuit caused by solder paste may exist, especially with the current promotion and application of lead-free processes. At the production site, some simple comparison tests can be adopted for verification: By comparing the production of different brands and types of solder pastes, select one that suits the production characteristics of your own product.

Shenzhen JJY Industrial Technology Co., Ltd. was established in2008years10Month is a provider of customized solder solutions integrating the research and development, production, customization, solutions and services of electronic solder. "JJY" has been selected for the Brand Power Demonstration Project [Solder Materials]. The floor area of JJY factory building5000It covers an area of over ten square meters and is equipped with multiple modern production, testing and experimental facilities. Lead-free solder products have all passed.SGSThe test is in full compliance with the EU standardsRoHSLatest instructionsREACHStandard......If you are interested in consulting, please feel free to call JJY!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account