Lead-free solder pasteHow to choose high-quality solder paste in electronic products? Nowadays, the pace of society is constantly advancing. Electronic devices such as mobile phones, computers, laptops, and smartwatches have become indispensable products in people's lives and work. These products are basically composed of circuit boards. Electronic components such as resistors, capacitors, diodes, and integrated circuits are closely combined with the circuit board through solder joints formed on the circuit board by solder paste. To achieve the electrical connection between components and ensure the smooth operation of electronic devices, now, let's have the editor of JJY explain to you how to choose a suitable solder paste?

How to choose high-quality solder paste?

1First, select the alloy components of the solder paste based on the assembly process, printed circuit board and components of the product(This mainly depends on the process conditions and usage requirements in industrial production as well as the performance requirements of solder paste).

2In industrial production, according to the product(Printed circuit board)Choose the solder paste that suits you based on the requirements for cleanliness and the different degrees of cleanliness after soldering. When adopting the no-cleaning process in production, it is necessary to select no-cleaning solder paste with low halogen content and no strong corrosive compounds. When using the solvent cleaning process, solvent-cleaning solder paste should be selected. When using the water cleaning process, water-soluble solder paste should be selected.BGA,CSPGenerally, high-quality no-clean silver-containing solder paste should be selected.

3According toPCBThe activity of solder paste should be selected based on the storage time of the components and the degree of surface oxidation.

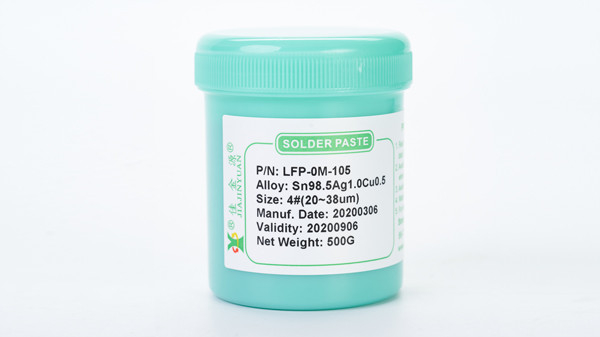

4According toPCBThe assembly density(Is there a fine spacing?)During the production process, the appropriate particle size of the alloy powder should be selected. Generally, the particle sizes of commonly used solder paste alloy powders are divided into four particle size grades, and fine spacing is usually chosen20-45um.

5According to the relevant provisions of the "General Specification for Tin-Lead Paste Solder", "The percentage of alloy powder in the solder paste.(Quality)The content should be65%to96%,Percentage of alloy powder(Quality)The deviation between the measured value of the content and the predetermined value on the order sheet shall not be greater than±1%" In actual use, the tin powder content of the selected solder paste is approximately90%The ratio of tin powder to flux on the left and right is approximately90:10;

6Reflow soldering requires that the device pins be firmly soldered, the solder joints be full and smooth, and there be one in the height direction of the device (resistor device) end1/3to2/3The height of solder climbing and the content of metal alloys in the solder paste have a certain influence on the thickness of the solder after reflow soldering (i.e., the fullness of the solder joint). To confirm the existence of this problem, relevant experts have conducted related experiments. The final experimental results are excerpted in the following table for reference: As can be seen from the above table, as the metal content decreases, the thickness of the solder after reflow soldering decreases. To meet the requirements for the amount of solder at the solder joint, it is usually selected85%~92%The content of solder paste.

Whether a solder paste is suitable or not mainly depends on its soldering quality. All the evaluation elements mentioned above are aimed at achieving a good soldering effect. By statistically analyzing the soldering quality data after reflow, the defect problems generated are analyzed and it is determined whether they are related to the quality of solder paste. Problems such as poor wetting or short circuit caused by solder paste may exist, especially with the current promotion and application of lead-free processes. At the production site, some simple comparison tests can be adopted for verification: By comparing the production of different brands and types of solder pastes, select one that suits the production characteristics of your own product.

The solder paste of Shenzhen JJY brand has gone through many years12A solder paste and wire manufacturer specializing in the annual research and development of solder paste, solder wire, solder wire, lead-free solder paste, leaded solder paste, solder rods, leaded solder paste, etc. Choose the solder paste of JJY brandSolder paste manufacturer.

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account