Solder paste is mainly a paste-like mixture composed of solder powder and flux, and is mainly used forSMTIn the processing industry, resistors, capacitors,ICWait for the electronic components to be solderedPCBOn the board. Solder paste is further divided into leaded solder paste andLead-free solder pasteLeaded solder paste and lead-free solder paste mainly include the following4Obvious differences in major aspects.

When in use, the lead-containing solder paste should be thoroughly stirred, and then added to the printing screen according to the set amount for printing. For those using the dot injection process, the dot injection amount must be adjusted properly. Under long-term printing conditions, the evaporation of flux in the solder paste will affect the demolding performance of the solder paste during printing. Therefore, the containers for storing solder paste cannot be reused(For single use only).

Storage: The remaining solder paste on the screen after printing should be stored in other clean containers. When using it again next time, check if there are any lumps or solidified conditions in the remaining solder paste first.

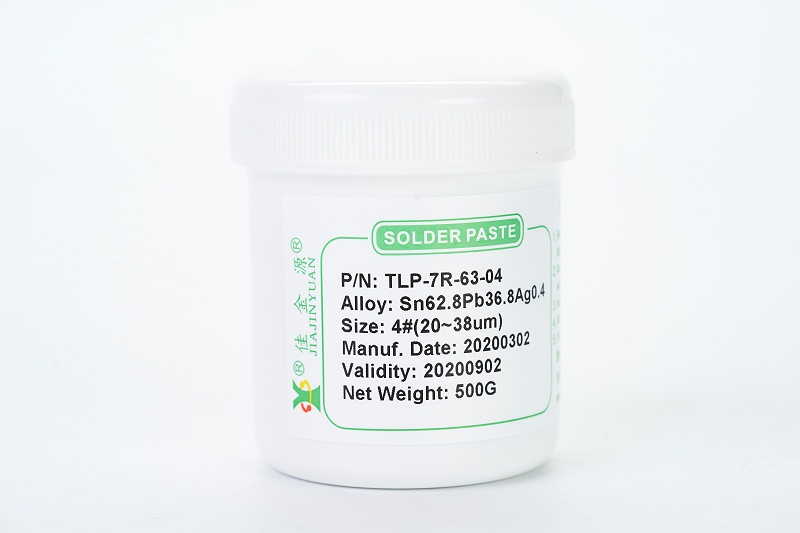

The difference between leaded solder paste and lead-free solder paste lies in the alloy powder,It is generally distinguished by the naked eye,It can be distinguished by color,It has lead and is grayish black in color,Lead-free, grayish-white. Make an accurate distinction.,It is to analyze whether the alloy powder contains lead. Lead-free solder paste is usually stored in green bottles. Also, open the cap and smell the odor. If the smell is strong, it is generally lead solder paste. It has a smell because it contains lead. Alloys with lead have a higher specific gravity, so they are packed in the same container500At that time, it was not filled to the brim. However, for lead-free solder paste, there are several types of solder pastes with different melting points, such asHigh-temperature solder pasteIts specific gravity is relatively low, so it is filled to the brim. However, for low-temperature solder paste, its specific gravity is also high, so it is not filled to the brim as much.

The differences between leaded and lead-free solder paste,First, alloy powder is different,It is generally distinguished by the naked eye,Second, it can be distinguished by color,It has lead and is grayish black in color,Lead-free, grayish-white. Make an accurate distinction.,It is to analyze whether the alloy powder contains lead components,Common solder paste in the market,The green bottle is filled with lead-free solder paste,The white bottle is filled with leaded solder paste.

If you want to know about solder paste, lead-free solder paste, solder paste and other soldering issues, partners are welcome to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together! The solder wire, solder paste and solder rods of JJY brand are always waiting for partners to come and take them together.

tags: Lead-free tin bars lead-free tin bar prices lead-free solder paste prices leaded tin bar prices

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account