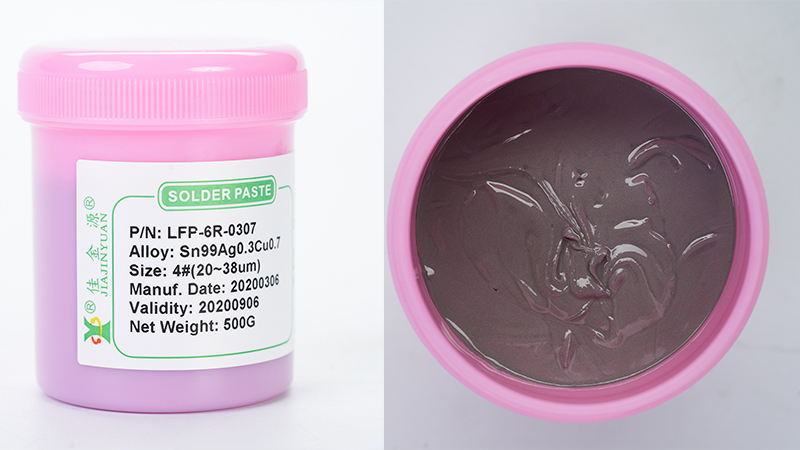

We believeSolder pasteIt is solder material. In the production process of electronic products, technicians play the role of first printing solder paste onPCBSubstrate Up. Install the components with the installer and firmly hold them through the welding furnace Welding The function of the component.The unused solder paste on the same day, if the next day When it is no longer in production, put it back in the refrigerator for storage and mark the time on the label.

Introduction to lead solder paste

Lead-containing solder pastes are all composed of a mixture of soldering flux components and alloy components. Tin and lead are the main components in the alloy composition it occupies, so it is called leaded solder paste.

It contains lead solder paste components

The composition of lead-containing solder paste depends on the type of solder paste. There are many alloy components for lead-containing solder paste. Tin and lead are the main components in the alloy of lead-containing solder paste. Besides these, the alloy of solder paste will always contain trace amounts of impurity metal elements (such as ferrotin). Zinc Copper Aluminium Silver Mercury (etc.)

Solder paste is accompaniedSMTA new type of welding material that emerged as The Times require. Solder paste is a complex system, which is a paste composed of solder powder, flux and other additives. Solder paste has a certain degree of viscosity at room temperature and can initially bond electronic components in the predetermined positions. At the soldering temperature, as the solvent and some additives evaporate, the components to be soldered are soldered together with the pads of the printed circuit to form a connection.

Medium-temperature solder paste

Tin-bismuth-silver alloy has a moderate melting point and is widely applicable. It performs exceptionally well in both surface mount and through-hole mounting. During printing, it has good moisture retention, ensuring stable printability and demolding performance. It can be continuously printed on steel screens8Hours,It has good solderability, good solder climbing, and full and bright solder joints.

ledIndustry useLow-temperature solder pasteWhen using low-temperature solder paste for reflow soldering, it is very likely to occurLEDWhen the tin adhering to the pad comes off, using silver-containing medium-temperature solder paste can solve the problem,It's mainly about cooling down after the furnace.

For those who want to know about solder paste, solder paste, low-temperature solder paste, solder wire and solder bar, welcome to consult Shenzhen JJY Industrial Technology Co., LTD. Let's learn and grow together!

Tel:+86 0755 88366766

Tel:+86 0755 88366766 Phone:+86 18938660310

Phone:+86 18938660310 Email:sales@jjyhanxi.com

Email:sales@jjyhanxi.com Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027)

Address:13/F,12/F, Building No. B,Qinghu Technology Park,Qingxiang Rd.,Qinghu Community, Longhua Subdistrict,Longhua District,Shenzhen City,GUANGDONG Province,P.R.C.(518027) Guangdong Public Security Backup 44030902002666 name

Guangdong Public Security Backup 44030902002666 name

WeChat

WeChat WeChat official account

WeChat official account